35

1

2

3

4

5

9 - SECTION D

SOLAR STATION UNIT 2 PLUS

HUB RADIATOR PLUS 250 - 400 SOLAR

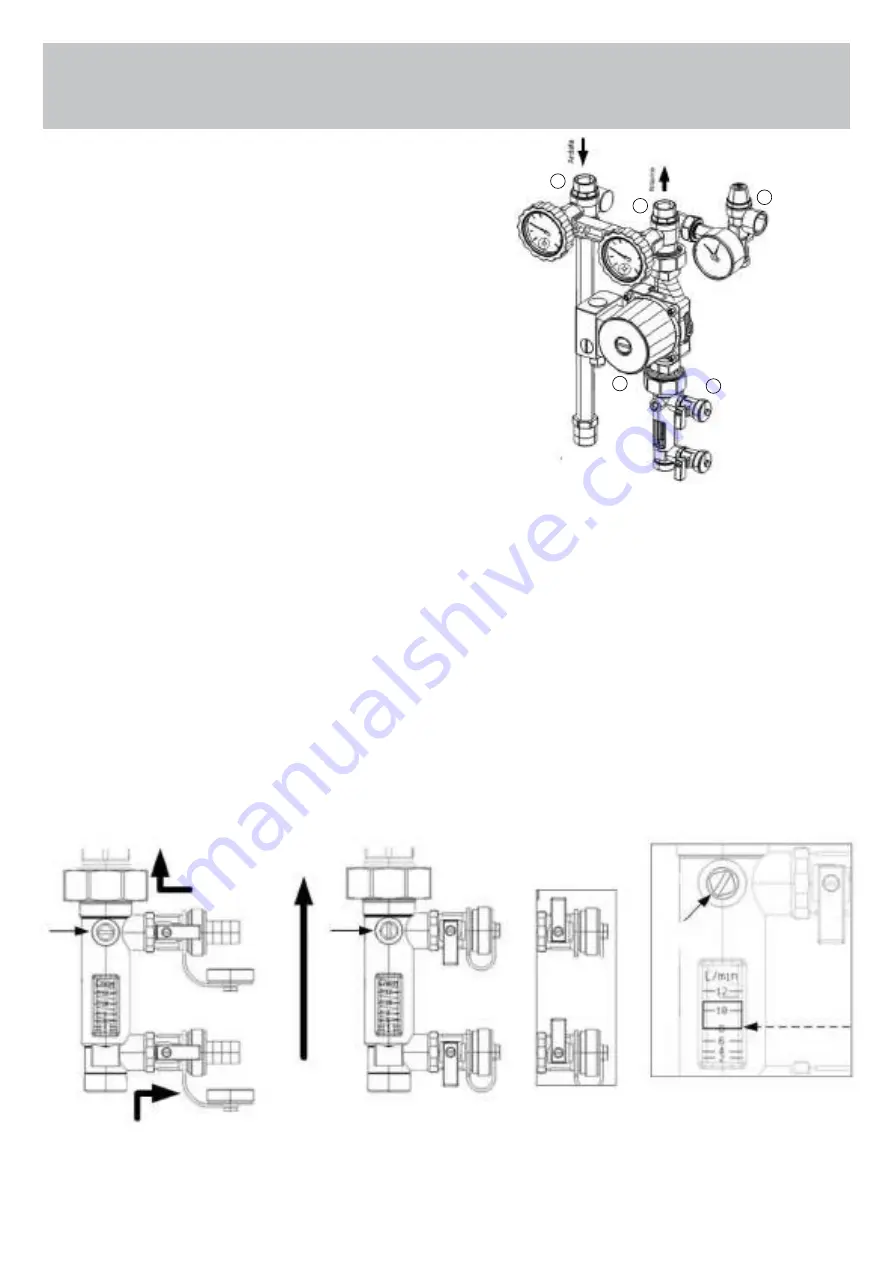

9.1 MAIN PARTS OF THE COMBINED CIRCULATION

GROUP FOR SYSTEMS SOLARI UNIT 2 PLUS

Round trip system

1 Ball valve on the delivery branch

(Thermometer with red ring and scale 0-120 °C)

with VNR (non-return valve) “Solar”

2 Ball valve on the return branch

(Thermometer with blue ring and scale 0-120

°C) with VNR (non-return valve) “Solar”

The “Solar” non-return valve inserted in the ball valve both on the

flow and return branches guarantees tightness and low pressure

drops.

To exclude the non-return valve, for example in case of system

emptying, turn the knob 45° clockwise.

Circulator

3 Manually adjustable 3-speed circulator.

Thanks to the tightness of the ball valves upstream and

downstream of the circulator, it can be removed without

emptying the system.

Security group

4 The CE and TUV certified safety safety group protects the

system from overpressures. It is calibrated at 6 bar beyond

which the group intervenes, and is also equipped with a

pressure gauge and connection to the expansion tank via an

optional 3/4 “flexible kit

Flow regulator

5 The regulator allows you to adapt the flow rate to your needs

of the system through a 3-way ball valve.

When the valve is in the closed position, normal circulation is

interrupted and it is possible to use the side tap to load the

system. There is a second side tap for draining. The proximity

of the 2 taps facilitates operations by minimizing the section

between loading and unloading.

The flow rate is indicated by the appropriate sliding cursor:

the feedback is immediate thanks to the proximity to the

regulating valve

9.2 Instructions for using the flow regulator when loading the system

(1)

Loading operations on the system:

Remove the cap from the side valves

and insert the hose holder.

Close the ball valve and open the side

loading and unloading valves.

Locking knobs of

loading / unloading;

Unscrew the fixing screw,

pull out the knob

and reinsert it rotated

of 180°

(2)

System commissioning:

Open the ball valve and close the side loading and unloading

valves. Remove the hose no longer used and screw the caps

back on.

To avoid accidental opening of the side taps, it is advisable to lock

the knobs in the closed position as shown on the side.

(3)

Adjust the flow rate by acting on the adjustment rod until the

desired flow rate is reached.

(NB)

the flow rate is indicated by pressing the lower profile of the

sliding cursor as a reference (see figure).

Discharge

Circulation

Load

valve

ball

closed

valve

ball

open

Adjustment

scope

Range indicated

in this example

8l / min