IB 6.2.7.7-3

1

2

Gap and Contact Wipe are inversely related;

increasing one decreases the other, and visa-

versa. Also, note that no more than one-half (1/2)

turn should be required when readjusting for

contact sequence.

After completing the contact sequence procedure,

recheck the Contact Wipe and gap for each pole.

If the specified Contact Gap, Contact Wipe and

contact sequencing cannot all be obtained, and it

is determined that the breaker is operating

properly, the interrupter is in need of replacement.

The front cover and interphase barrier assembly

can now be reinstalled. Return the rack screw to

its original position by turning it counterclockwise

approximately two to three turns until it stops.

Closing and Opening Times

After the operation intervals, it is recommended

that the Closing and Cpening Times be checked.

This can be done by use of a cycle counter, travel

recorder or oscillograph to monitor the time from

coil energizing to contact kiss (closing) or part

(opening).

Note: Normally, the Closing Time is not critical.

The breaker performance is satisfactory if the

Closing Speed, Opening Speed and Opening

Time are within specification. See Table A3 in the

Appendix for the nominal values for these

parameters.

The circuit breaker closing and opening times

should be within the time ranges for normal

operation.

Note the following:

•

Times are from signal initiation to primary

contact kiss (make) or break.

•

Times for DC controls supplied by a rectified

unconditioned power source, and all AC

controls, may wander by as much as ±4ms

due to the "current-zeroes" associated with

such currents.

•

Below 0°C, the closing times will increase

(but with no reduction in closing force), and

opening times will usually be within the

limits.

•

Adjustments to correct times, if found to be

outside limits, are critical and the nearest

District Office should be contacted for

recommendations.

Closing and Opening Speeds

The Closing and Opening speeds of the Primary

Contacts can be determined by use of a travel

recorder, which records their linear travel versus

time. The output can be fed into a travel recorder

or oscilloscope.

Before the Closing and Opening speeds are

checked, the Contact Wipe should first be

inspected. This is because, in addition to the

energy provided by The Opening Springs, the

Contact Springs provide additional acceleration

energy through the wipe distance upon contact

part. As the Primary Contacts erode, the Contact

Wipe decreases, and the opening speed will

decrease. Speed should still be within

acceptable limits if the wipe is still within limits.

Refer to Table A3 in the Appendix.

WARNING

Do not attempt to increase the opening speed by

readjusting the push rod to gain more contact wipe.

If either of the speeds is too slow, and the Contact

Wipe is within the limits specified, examine the

breaker for any moving parts that appear to be

binding. If none can be found, consult the factory

for assistance.

Operating Mechanism

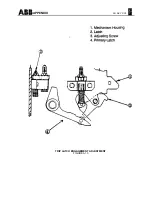

Trip Latch Engagement (Bite) (See Figure

A10).

The Latch Engagement Adjusting Screw (3) is

located

at the right of the right-hand mechanism

housing (1). It can be reached easily from the top

of the breaker, after removal of the top cover

plate.

To adjust the Latch (2) Engagement, proceed as

follows: