3

a) Power

transfer

Power is transfered from the motor through a gear

wheel and threaded shaft to the operating axel. The

direction of operation for open and close control can

be reversed by changing the motor’s direction of

rotation. The threaded shaft gear is assembled from

a round stainless steel shaft and one or two bronze

nuts. The shaft is self-locking which means that the

operating device cannot be rotated with a force from

the operating axel. This also applies if the operating

device is in the central position. The nuts transfer

the power through the specially formed lever to the

operating axel. The lever is formed so that it can be

locked in the extream position.

By disengaging the coupling ring, manual operation can

be performed by means of the control lever.

Both the gear wheel and the threaded shaft are

greased with low temperature grease which ensures

correct operation in temperatures as low as –50°C.

b) Mechanical

locking

The unit is fi tted with a locking device which also

includes a switch to prevent the motor from operat-

ing. The locking unit mechanically locks the operating

device and is strong enough to withstand the driving

force of the motor if the blocking switch S12 fails. The

locking unit locks both the motor operating device and

the manual operating device.

c) Electrical

operation

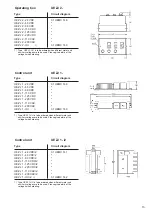

Motor operating device type UEMC 40 A1_, B1_,

and D1_ are fi tted with a lower level of electrical

components, and require a separate control unit, such

as UEZJ 1 or UEZJ 2.

Refer to circuit diagram: 31 UEMC 79.

Motor operating device type UEMC 40 A2_, B2_, and

D2-_are equipped with a complete control system

including contactors, I- and O-push buttons and m.c.b.

Refer to circuit diagram: 31 UEMC 81.

1. General

The UEMC 40 A_, UEMC 40 B_ and UEMC 40 D_ motor

operating devices are intended for indoor mounting on

medium voltage disconnectors and earthing switches.

The operating device is reliable in changing temperature

and humidity conditions.

Operation can be performed both electrically or by

means of the manual operating lever. Operating time

is about 5...8 s depending on the type of device and

loading conditions.

2. Standards

The motor operating device complies with

– IEC 265 (1983)

– VDE 0530 motor voltage test

3.

Transport and storage

The motor operating device can be transported in any

position, and should be stored indoors in a dry area.

4. Construction

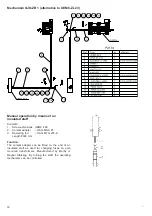

Fig. A

1. Power

unit

2. Limit

switch

3. Guide

pin

4. Coupling

ring

5. Locking

catch

6. Motor

7. Terminal

block

8. Control push button

9. M.c.b.

10. Contactor

11. Lever

12. Nut

Summary of Contents for UEMC 40 A Series

Page 26: ...26 26 ...

Page 50: ...50 50 ...

Page 74: ...74 74 ...

Page 86: ...86 86 ...

Page 87: ...87 ...