www.abb.com/jokabsafety 25

2TLC172213M0201, rev. B

10 Technical data

Manufacturer

Address

ABB JOKAB SAFETY

Varlabergsvägen 11

434 39 Kungsbacka

Sweden

Ordering data

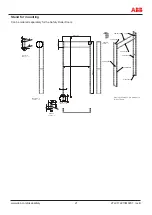

Safety Roller door + viewing window. Viewing window with weld splash protection.

Daylight height & Daylight width.

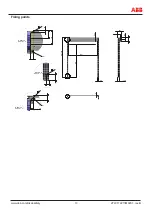

Mechanical characteristics

Maximum size, door cloth

10 m²

If a larger size is needed, contact ABB Jokab Safety AB.

Maximum width

4000 mm

Maximum height

3500 mm

Speed, roller door

0.7 – 1.0 m/s up/down

Max. number of cycles/minute

3 (during continous operation 24 hours a day)

Material frames

Aluminum extrusion

Material upper bracket

4 mm steel painted black

Electrical characteristics

Driving unit

Three-phase motor

200-415 VAC 50-60 Hz

General

Protection class

Motor and gearbox are delivered with IP54 rating.

Colour

Frame - aluminium, door cloth - grey

Other colours available on request.

Door fabric material

Multi-layer polyester fabric cloth with PVC, 2 mm thick or transparent PVC. The viewing window can

also be supplied with protection against welding flash light. (Removes 99% of the UV-transmision from

the welding process)

Door fabric colour

Grey (RAL 7038), can be supplied with recessed window (only in full width). Other colours are

available.

Sound absorption

approx. 10 dB

Ambient temperature

0˚C to +55˚

When operating in temperatures below -5˚C, the oil in the gear-box should be replaced with an oil

suitable to withstand cold temperatures.

Durability towards chemicals

Ammoniac, sodium hydrate, phosphoric acid, tartaric acid, oxalic acid, hydrochloric acid, citric acid,

acetic acid, oil, detergent, calcium chloride (contact ABB Jokab Safety for more specifications)

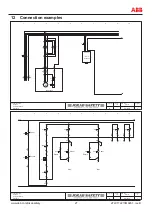

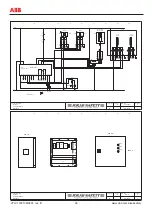

Safety

Control monitoring unit for roller

door

ABB Jokab Safety´s Safety-PLC, Pluto

Outputs

4 safe outputs for connection to machine/plant.

Monitoring of position of the roller

door

2 Eden sensors

one on each side of the door.

Contact strip

Mounted on the bottom frame of the door fabric.

The door motion is reversed if the contact strip is compressed.

Safety level

Category 4/PL e, in accordance with EN ISO 13849-1