6

INS/ANAINST/025-EN Rev. B

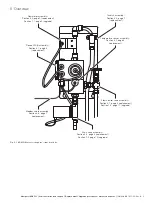

| Navigator ADS551 | Low level dissolved oxygen | Replacement / Upgrade procedures – wet section spares

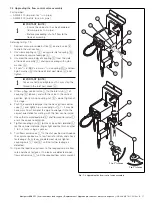

6.4 Replacing the drain valve assembly and drain valve

cable assembly

Part number:

— AW502 056

Referring to Fig. 6.5:

1.

Depress manual override button

A

on drain valve

B

to

drain the wet-section.

2.

Disconnect clip-on cable connector

C

from the end of the

drain valve coil housing by depressing clip

D

.

3.

Disconnect the drain tube from barbed outlet connector

E

on the bottom of drain valve

B

.

4.

Lock hex coupling

G

and rotate nut

H

clockwise to

release couplings. Remove the valve assembly, complete

with coupling

G

. Remove coupling

G

from the valve

assembly and fit to new valve, complete with new bonded

seal

I

.

5.

If fitting a new drain valve cable assembly, remove the

wet-section cover as detailed in step 1 of Section 6.1, page

4, loosen the drain valve cable gland in the wet-section

PCB housing and proceed with steps 6, 7and 8 (below).

If using the existing cable, re-connect the clip-on cable

connector

C

to the end of the drain valve coil housing.

6.

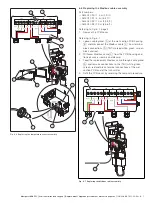

Disconnect the drain valve cable from the terminal block –

see Fig. 6.7, page 7 and discard the cable.

7.

Feed the replacement drain valve cable through the cable

gland and make connections to PCB wet-section terminals

TB3 (see Fig. 6.3, page 5) and at the transmitter (see

Operating instruction OI/ADS550-EN).

8.

Connect the drain valve clip-on cable connector

C

to the

end of the drain valve coil housing.

9.

Reconnect the drain tube to barbed outlet connector

E

on bottom of drain valve

B

.

6.5 Replacing the temperature sensor assembly

Part number:

— AW502 220

Referring to Fig. 6.5:

1.

Depress manual override button

A

on drain valve

B

to

drain the wet-section.

Referring to Fig. 6.6, page 7:

2.

Remove and retain 4 flowcell PCB cover fixing screws and

washers

C

and remove PCB cover

D

.

3.

Remove flowcell PCB housing gasket

E

.

4.

Loosen cable gland

F

.

5.

Loosen terminal screws

G

and disconnect temperature

sensor cables

H

from TB5.

6.

Withdraw sensor cables

H

from flowcell PCB housing

I

through cable gland

F

.

7.

Unscrew the knurled nut on temperature sensor assembly

J

and carefully withdraw the temperature sensor from

flowcell housing

K

.

8.

Ensure a new O-ring

L

is securely located on the new

temperature sensor, insert the sensor into flowcell housing

K

and tighten the knurled nut on temperature sensor

assembly

J

finger-tight.

9.

Feed cables from the new temperature sensor through

cable gland

F

, make connections correctly at TB5 and

tighten screws

G

.

10. Tighten cable gland

F

.

11. Refit flowcell PCB housing gasket

E

ensuring it is located

correctly.

12. Refit PCB flowcell cover

D

and secure with 4 flowcell

PCB cover fixing screws and washers

C

.

Fig. 6.5 Replacing the drain valve assembly and drain valve cable assembly

A

B

C

D

E

F

G

H

I

IMPORTANT (NOTE)

Check existing small O-ring

L

fitted on the end

of the temperature sensor is withdrawn along

with temperature sensor assembly

J

.