2

INS/ANAINST/025-EN Rev. B

| Navigator ADS551 | Low level dissolved oxygen | Replacement / Upgrade procedures – wet section spares

3 Health & Safety

4 Overview

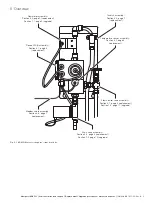

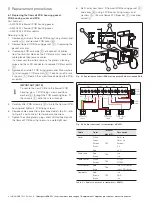

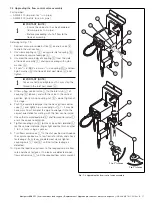

Flowcell PCB assembly, PCB housing cover, PCB housing gasket

(replacement – page 4):

— AW502 228 flowcell PCB housing gasket

— AW502 227 flowcell PCB housing cover

— AW502 225 PCB assembly

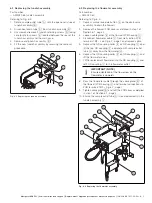

Tundish assembly

(

replacement – page 5)

:

— AW502 065 tundish assembly

Flowmeter assembly (replacement – page 5 / upgrade – page 9)

:

— AW502 250 flowmeter assembly (upgrade kit)

— AW502 060 flowmeter assembly (replacement kit)

Drain valve assembly (replacement – page 6 / upgrade – page 10)

:

— AW502 240 drain valve assembly (upgrade kit)

— AW502 056 drain valve assembly (replacement kit)

Temperature sensor assembly

(

replacement – page 6)

:

— AW502 220 temperature sensor assembly

Modbus cable assembly (replacement – page 7)

:

— AW502 090 1.5 m (4.9 ft. cable)

— AW502 091 5 m (16.4 ft. cable)

— AW502 092 10 m (32.8 ft. cable)

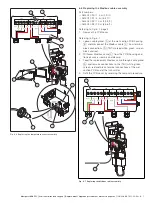

Flow control valve (replacement – page 8 / upgrade – page 11)

:

— AW502 270 flow control valve assembly

(upgrade kit – imperial)

— AW502 275 flow control valve assembly

(upgrade kit – metric)

— AW502 068 flow control valve assembly

(replacement kit – imperial)

— AW502 069 flow control valve assembly

(replacement kit – metric)

WARNING – Bodily injury

These procedures must be carried out by a trained

technician.

Chemical

– Ensure personal protective equipment (PPE) such

as gloves and eye protection are worn during any

maintenance.

– Observe all health and safety procedures for

handling chemicals.

– To familiarize yourself with handling precautions,

dangers and emergency procedures, always review

the Material Safety Data Sheets prior to handling

containers, reservoirs and delivery systems that

contain chemical reagents and standards.

– Take care if cleaning any spillages and observe all

relevant safety instructions. Wipe up any spillages

using clean water.

Electrical

– Isolate all high voltage supplies to the transmitter

before performing replacement procedures.

– The wet-section is vulnerable to electrostatic

damage. Wear an anti-static strap or dismantle the

wet-section on an anti-static workbench.

– Ensure all electrical connections are kept dry at all

times.

General

– Shut off the external sample supply to the

wet-section and drain the flowcell - refer to the

wet-section Operating instructions (OI/ADS550-EN)

for flowcell drainage options.

– When a procedure is complete, restore power to

the transmitter and sample to the wet-section at the

correct flow rate. If necessary, calibrate the

wet-section – refer to the wet-section Operating

Instructions (OI/ADS550-EN) for calibration

instructions.

– Perform general cleaning of the wet section using a

damp cloth only – mild detergent can be used as a

cleaning aid. Do not use Acetone or any organic

solvents.