4 Repair

4.3.5. Replacement of complete arm system

235

3HAC020993-001 Revision: G

©

Co

py

rig

h

t 200

4-

200

8 ABB. All righ

ts reser

v

ed.

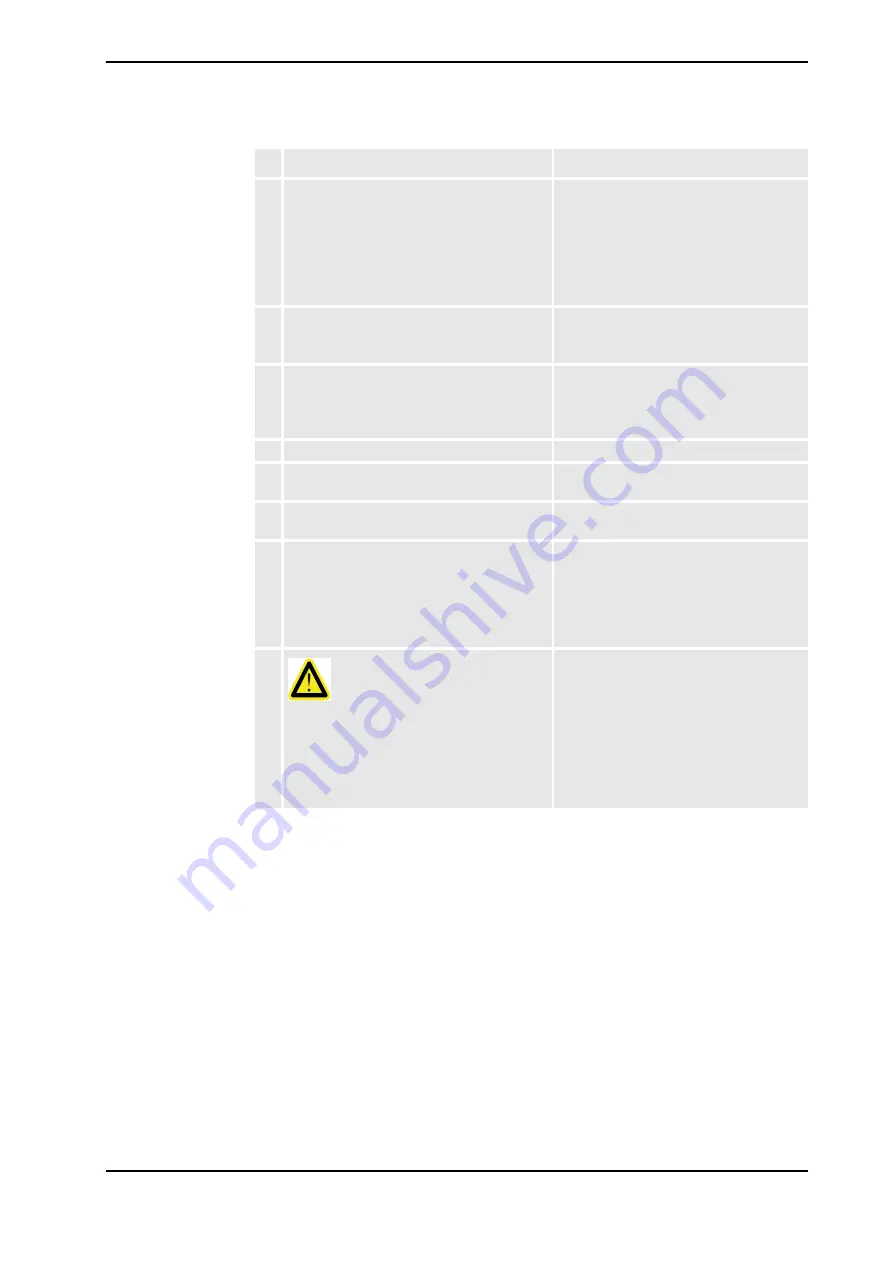

8. Remove the guide pins and secure the arm

system to the base with its 24

attachment

screws and washers.

Shown in the figure

M12 x 110, 12.9 quality UNBRAKO.

Tightening torque: 110 Nm.

Reused screws may be used, providing

they are lubricated as detailed in section

before fitting.

9. Refit the

block for calibration

at the bottom of

the frame.

Shown in the figure

10. Refit the motor axis 1.

Detailed in section

.

Detailed in section

.

11. Refit the cabling in the base.

12. Perform a leak-down test of the gearbox axis

1.

Detailed in section

13. Refill the gearbox axis 1 with lubricating oil.

Detailed in section

.

14. Recalibrate the robot.

Calibration is detailed in a separate

calibration manual, enclosed with the

calibration tools.

General calibration information is

included in section

.

15.

DANGER!

Make sure all safety requirements are met

when performing the first test run. These are

further detailed in section

test run may cause injury or damage! on

page 38

Action

Note/Illustration

Continued