4 Repair

4.4.5. Replacement of lower arm shaft

267

3HAC020993-001 Revision: G

©

Co

py

rig

h

t 200

4-

200

8 ABB. All righ

ts reser

v

ed.

Refitting, lower arm shaft

The procedure below details how to refit the lower arm shaft.

Action

Note/Illustration

1. Clean the shaft with

isopropanol

and lubricate it

with

glycerin

.

Art. no. is specified in

!

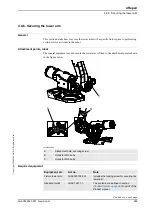

2. If the robot is going to work in a water jet application

cell:

Apply Mercasol 3106 on the Support shaft axis 2.

•

Apply Mercasol 3106 on both sides of the

thrust washer, all around the bearing and on

surface on the shaft.

xx0600003137

•

A: Mercasol on marked

areas.

3. Push the shaft in by hand.

4. Refit the

thrust washer

to the shaft.

Also shown in the figure

Components, lower arm shaft on

page 263

5. Apply the

press device, axis 2 shaft

against the

shaft.

Art. no. is specified in

!

6. Tighten the M16 nut.

Tightening torque: 20 Nm.

7. Fit both the

hydraulic pump

and the

glycerin pump

to the press device.

Art. no. is specified in

.

The attachments on the tool are

shown in the figure

refitting of axis 2 shaft on page 265

8. Set the

indicator

on the press device to zero.

Shown in the figure

for refitting of axis 2 shaft on page

265

.

9. Press in the shaft with the hydraulic cylinder by

setting the pressure of the hydraulic pump to

approximately 35-55 MPa and the pressure of the

glycerin pump to 55 MPa.

10. Increase the pressure of the both pumps alternately

until the correct value is reached with the indicator

on the press tool.

Correct value: 2.45 mm ± 0.15 mm.

Note!

Do not exceed the limit of

maximum pressure classified for

the pumps!

11. When a correct value is reached, release the

pressure from the glycerin pump first, then from the

hydraulic pump (approximately 1/2 minute after), in

order to avoid movement of the shaft.

12. Remove the press device, axis 2 shaft.

A

A

Continued

Continues on next page