4 Repair

4.4.3. Replacement of upper arm

3HAC020993-001 Revision: G

254

©

Co

py

rig

h

t 200

4-

200

8 ABB. All righ

ts reser

v

ed.

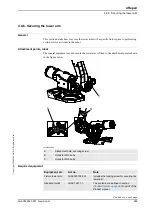

5. In order to release the brake of the axis 3 motor,

connect the 24 VDC power supply, after

removing the motor cover.

Connect to connector R2.MP3

•

+: pin 2

•

-: pin 5

6. Fasten the

lifting tool (chain)

onto the lifting eye,

the lifting device and an overhead crane.

Art. no. is specified in

!

7.

CAUTION!

The complete upper arm weighs 380 kg without

any additional equipment fitted! Use a suitable

lifting device to avoid injury to personnel!

8. Lift the upper arm and move to its mounting

position.

Make sure the lift is done completely level!

9. Fit in the gearbox attachment holes with the

attachment holes on the lower arm with the

guide pins.

It may be necessary to turn the gear by rotating

the motor pinion with a

rotation tool, motor

beneath the motor cover.

Art. no. is specified in

!

xx0200000165

The rotation tool is used beneath the

motor cover, directly on the motor shaft

as shown in figure above.

•

A: Rotation tool

10. Fit the three

washers

to be placed beneath the

attachment screws.

Shown in the figure

!

11. Insert 31 of the 33

attachment screws, upper

arm

into the attachment holes in the lower arm.

Do not remove the guide pins until the

attachment screws are tightened as detailed

below.

Shown in the figure

!

Removing the plastic mechanical stops

may be required before fitting the upper

arm.

If guide pins are removed before the

screws are tightened, the sealing can

be involuntarily moved into wrong

position.

12. Secure the lower arm to gearbox axis 3, with

the attachment screws.

33 pcs: M12 x 50; 12.9 quality

UNBRAKO, tightening torque: 120 Nm.

Reused screws may be used, providing

they are lubricated as detailed in

section

before fitting.

13. Remove the guide pins and fit the two

remaining attachment screws. Tighten them as

detailed above!

Action

Note/Illustration

Continued

Continues on next page