GETTING STARTED

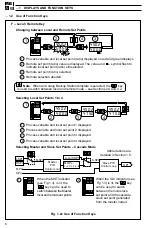

Fig. GS.1 Setting the Parameters

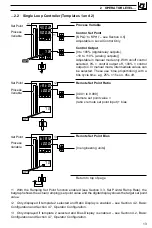

Note. With the

above configuration,

no alarms or limits

have been set and

advanced functionality

(gain scheduling, set

point sources etc.) has

not been enabled.

Step 3 – Setting the Parameters (Fig. GS.1)

A

Power-up the instrument. Press the

and

keys simultaneously and hold for

3 seconds to advance directly to Level 6 – Basic Configuration.

B

Set the appropriate application template, output type and control action. Use the

key to advance between frames and upper

and

keys to adjust the

default values – see Section 4.2 for further information.

Note. When the output type has been selected, the available inputs and outputs

default to the settings shown in Table B on the rear fold-out.

C

If you are not using 4 to 20mA inputs, then select Level 7 using the upper

and

keys and set up Analog Inputs I/P1 to I/P3 to suit your process – see Section 4.3.

D

Controller templates only:

Select Level 2 using the upper

and

keys and set the tune parameters:

• Analog or Motorized Valve Control – set the Proportional, Integral and

Derivative terms.

• Time Proportioning Control – set the Cycle Time, Hysteresis and P, I & D Terms

• Heat/Cool Outputs – set the points at which the Output 1 and Output 2

become active.

E

Press

to return to the Operating displays.

F

Adjust the set point to the required value.

Your COMMANDER 500 is now in operation

APPL

LEV.6

INPt

LEV.7

tUNE

LEV2

B

C

D

+

A

01.SL

t.APP

ANLG

O.tYP

rEV

C.ACt

50

FrEJ

E

50.1

50.5

50

50.1

50.5

50

F

50.1

50.5

50