21

2

OPERATOR LEVEL…

2.7

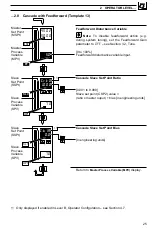

Cascade Control (Templates 11 and 12)

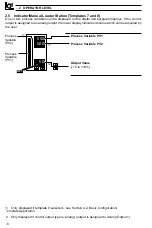

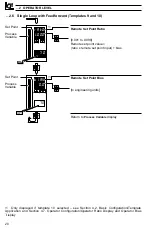

For cascade control, two internally-linked PID controllers are used, with the first (master) PID

controller providing the set point for the second (slave) controller. The master output is weighted

using the cascade ratio (C.rtO) and bias (C.bIA) values to create the slave set point value.

Fig. 2.6 Cascade Controller

Master Process Variable (MPV)

Master Control Set Point (MSPt)

['SPLO' to 'SPHI' – see Section 4.5]

Adjustable in local control only.

Slave Control Output

[0 to 100%] (–10 to 110% for analog outputs)

Adjustable in manual mode only.

Note. With template 12 the

L

L

R

key can be used

to change between local/remote set point values.

Slave Process Variable (SPV)

Slave Set Point (SSPt)

['SPLO' to 'SPHI' – see Section 4.5]

Adjustable in manual or local slave set point modes

only.

Note. The

L

L

R

key can be used in this frame to

change between cascade and local slave set points.

Continued…

•1

With the Ramping Set Point function enabled (see Section 3.3, Set Points/ Ramp Rate), the

bargraph shows the actual (ramping) set point value and the digital display shows the target set

point value.

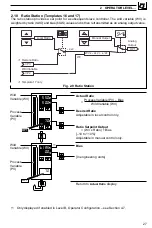

RSPt

MPV

I/P3

I/P1

I/P2

OP1

Local

Set Point

Remote Set Point

input

Master PV Input

Slave PV Input

Slave Set

Point

Slave PID

Control Loop

SPV

Master

PID

Control Loop

•1

•1 Template 12 Only

LSPt

SSPt

L

L

R

Manual Output

RSPt x

rAtO

+

bIAS

M.OP x

CrtO

+

CbIA

L

L

R

SSPt

M.OP

450.2

500.0

Master

Set Point

(MSPt)

Master

Process

Variable

(MPV)

70

OP1

450.2

500.0

SLV

70

OP1

MST

Slave

Set Point

(SSPt)

Slave

Process

Variable

(SPV)

•1

•1