6

C1 3 0 0/A DVA NCE D CI RCU L A R CH A RT R ECOR DE R

| C I/C 1 3 0 0 - EN R E V. C

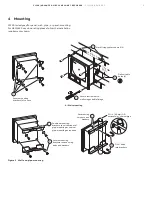

…4 Mounting

NOTICE

• The recorder can be inserted into a panel cut-out of any size between the minimum and maximum dimensions illustrated,

provided the cut-out is positioned centrally relative to the fixing holes. If the panel cut-out is larger than the maximum, a

locally manufactured adaptor plate is required.

• If panel-mounting to NEMA 4X hosedown standard is required, a continuous bead of suitable silicon sealant must be applied

between the case flange and the panel. Do not use the optional gasket.

Figure 4 Panel-mounting

Minimum cut-out dimensions

Maximum cut-out dimensions

Secure in panel using

four bolts, nuts and washers

Drill four suitable holes

Dimensions in inches (mm)

Mark four mounting holes

4 holes 0.281 dia.

or tap for ¼ in. thread

14.00 (355.6)

12.72 (323.08)

minimum

0.20 (5.0)

Ensure cut-out positioned centrally

between mounting holes

13.7 (348.0)

maximum

14.6

(371.0)

maximum

12.72

(323.08)

minimum

11.25

(285.8)

14.19

(360.4)

1.70

(43.2)

0.64 (16.25)

0.15 (3.8)

minimum

0.15 (3.8)

minimum

Locate instrument

in cut-out

Optional gasket

Cut hole in panel

4

5

3

2

1