Operators and Maintenance Manual

Measuring module

EMS DAQ R02.01

Page

11/18

Copyright:

Auto & Aero Technologies Sp. z o.o.

Mazowiecka 10/5, 20-723 Lublin, Poland

■

email: [email protected]

■

www.aatech.pl

listed in Table 3. The records of threshold crossing contain the following

information:

a)

Type of occurrence;

b)

Number of occurrences of each type;

c)

Moment of occurrence

defined by the number of system’s starts from

the fact of installing the system until the occurrence, total operation

time of the system from its last start until the occurrence, and total

engine operation time (HOOBS) until the occurrence.

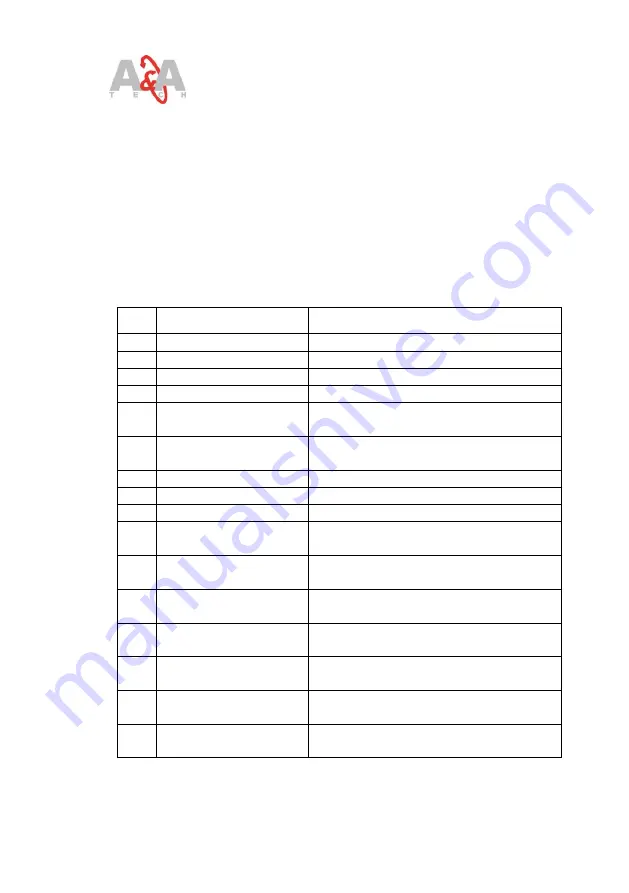

Tab. 3

Types of threshold crossings recorded by EMS DAQ R02.01 Module

No.

Signal

Threshold levels

1

Engine speed

> 5500 rpm, if present for more than 5 min

2

Engine speed

> 5800 rpm

3

Rotor speed

> 450 rpm

4

Inlet air pressure

> 46 inHg

5

Oil pressure

< 1 bar, if engine speed greater than 900

RPM

6

Oil pressure

> 7 bar, if engine speed greater than 900

RPM

7

Oil temperature

> 130°C

8

Oil temperature

> 130°C,

if present for more than 15 min

9

Oil temperature

> 150°C

10

Oil temperature

< 50°C,

if rotor speed greater than 200

RPM

11

Cylinder head

temperature

–

sensor 1

> 110°C

12

Cylinder head

temperature

–

sensor 1

> 110°C,

if present for more than 30 min

13

Cylinder head

temperature

–

sensor 1

> 120°C

14

Cylinder head

temperature

–

sensor 2

> 110°C

15

Cylinder head

temperature

–

sensor 2

> 110°C,

if present for more than 30 min

16

Cylinder head

temperature

–

sensor 2

> 120°C