19

lines with air or water and clear or replace the blocked portions

of the line as necessary. Note that areas of the drain line which

include a sag or low spot in the line will also form a condensate trap

which can be removed by levelling the tube and does not indicate

a blocked system.

Inspect the metal vent drain and vent collector drain connectors

at six month inter vals. Remove the hoses from the connections,

then check with a small wooden dowel or plastic rod passed up

through the metal con nection to insure the passage is clear,

using caution to not bend or damage the connector. Call a

qualified service agent to inspect and correct the problem if any

obstructions are found in the connectors. Replace all hoses and

clamps immediately after inspec tion and before starting the boiler

in accordance with the lighting and operating Instructions.

DO

NOT OPERATE THE BOILER UNLESS ALL CONDENSATE

DRAIN LINES ARE PROPERLY CONNECTED AND WORKING.

When a means to neutralize condensate has been installed

you must also follow operating, inspection and maintenance

procedures specified by the manufacturer of the product. Inspect

the installed device to insure that it does not cause condensate

to remain in the boiler or vent for any reason.

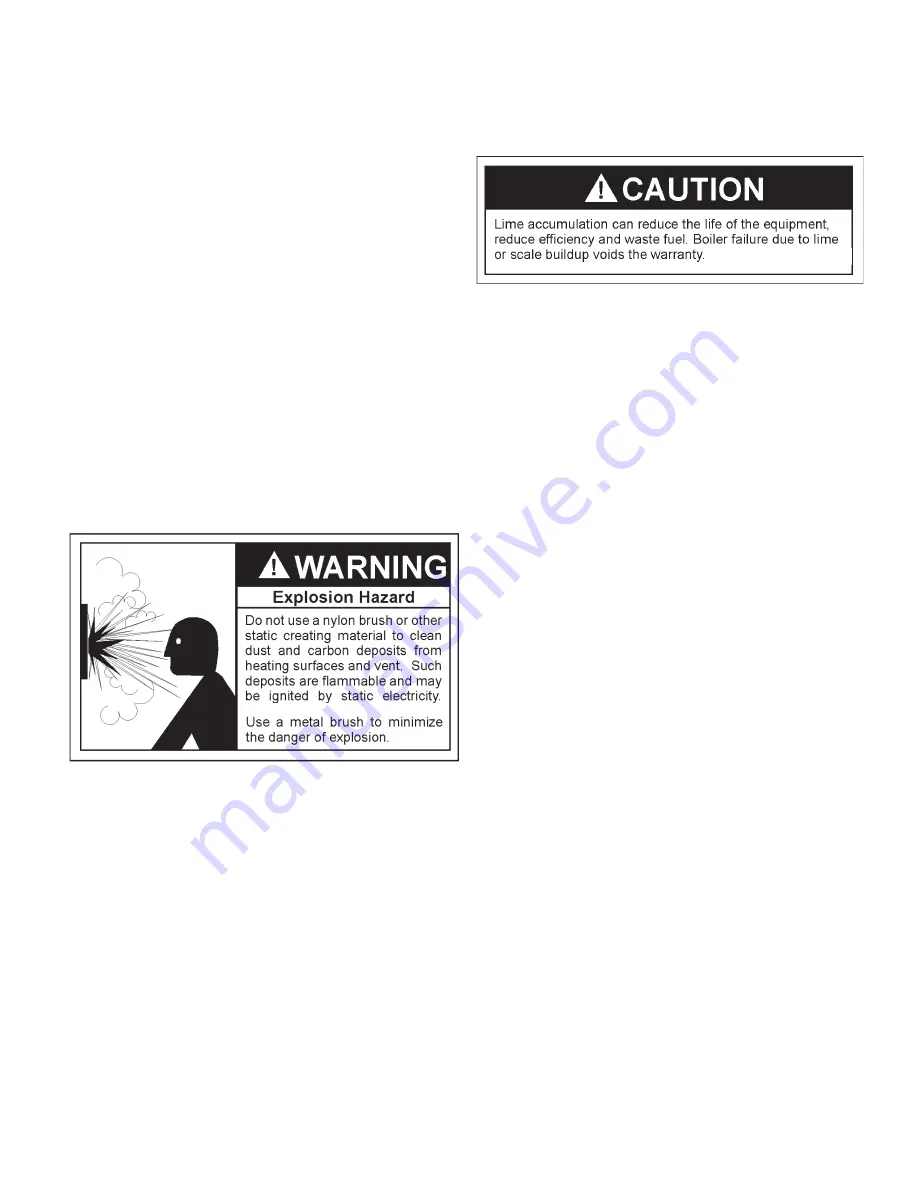

VENTING MAINTENANCE

It is recommended that the intake and exhaust piping of the

appliance be checked every 6 months for dust, condensate leakage,

deterioration and carbon deposits.

Qualified service agent should follow this procedure when the

boiler’s intake and exhaust piping need cleaning:

1. Turn off the electrical power, and manual gas shut-off.

•

Allow boiler parts to cool before disassembly.

2. Remove the vent pipe.

•

Check parts and chimney for obstructions and clean as

necessary.

3. Remove burner from boiler and other metal parts as required

to clean as necessary.

•

Refer to parts list for disassembly aid.

4. Clean and reinstall the parts removed in steps 2 and 3.

•

Be sure the vent pipe has a minimum upward pitch of 1/4"

per foot (2cm/m) of length and is sealed as necessary.

5. Restore electrical power and gas supply to boiler.

•

Check for gas leaks and proper boiler and vent operation.

HEAT EXCHANGER PREVENTIVE

MAINTENANCE

In most water supply systems solids exist. As the water is heated, these

tend to drop out depositing as scale or lime. This scale must be removed

before the heat exchanger tubes become blocked.

DELIMING

The amount of calcium carbonate (lime) released from water is

in direct proportion to water temperature and usage. The higher

the water temperature or water usage, the more lime deposits are

dropped out of the water. This is the lime scale which forms in

pipes, boilers and on cooking utensils.

The usage of water softening equipment greatly reduces the

hardness of water. However, this equipment does not always

remove all of the hardness (lime). For this reason it is recommended

that a regular schedule for deliming be maintained.

The time between cleaning will vary from two to six months

depending upon water conditions and usage. A change

of approximately 5

°

F (3°C) in the normal temperature rise

through the boiler is usually an indication that scale should

be removed. For long life, copper or brass is recommended

for all valves, pipe and fittings.

TUBE CLEANING PROCEDURE

MECHANICAL REMOVAL OF DEPOSITS

Establish a regular inspection schedule, the frequency depends

on the local water conditions and severity of service. Do not let

the tubes clog up solidly. Clean out deposits over 1/16” (1.6mm)

thickness.

To service heat exchanger tubes, remove return header casting on

the side opposite the water connections. Use a U.S. standard 5/8”

deep socket ratchet to remove the nuts, exposing the tube ends.

Inspect to ensure tubes are free of scale and deposits. If scaled,

remove deposits with a stiff wire brush or mechanical tube cleaner

to bare metal. Reinstall return header casting. Flush system.

Note: Removal of the heat exchanger is not required.

REPLACEMENT PARTS

Replacement parts may be ordered through A. o. Smith dealers,

authorized servicers or distributors. Refer to the Yellow Pages for

where to call or contact (in United States) the

A. O. Smith Water

Products Company, 500 Tennessee Waltz Parkway, Ashland

City, TN 37015, 1-800-433-2545 or (in Canada) A. O. Smith

Enterprises Ltd., 768 Erie Street, Stratford, Ontario, Canada

N5A 6T3, 519-271-5800.

When ordering parts be sure to state

the quantity, part number and description of the item including the

complete model and serial number as it appears on the product.

Refer to the parts list (P/N 212802-002) for more information.

For Technical Assistance call A. O. Smith Technical Information

Center at 1-800-527-1953.

Summary of Contents for VF VB 500

Page 3: ...3 GENERAL SAFETY...

Page 6: ...6 CONNECTION DIAGRAM...

Page 7: ...7...

Page 8: ...8 Figure 1 SCHEMATIC DIAGRAM VB VW 500 750 1000 SCHEMATIC DIAGRAM...

Page 9: ...9 LIGHTING OPERATION INSTRUCTIONS FOR MODELS VB VW 500 750 AND 1000...

Page 20: ...20 notes...

Page 21: ...21 notes...

Page 22: ...22 notes...