Page 15

Pro-120 controller instructions

18 Common faults

There are no ‘common’ faults: as soon as 4QD find a

fault which occurs which can be prevented, we try to

alter the design to eliminate it. This makes it difficult

to give you sensible fault finding tips - but it does

improve our product!

Most controllers returned for attention are either nor

faulty or have been damaged by ‘foreign bodies’:

nuts and bolts in the works or water etc.

There's a lot more service and fault finding info on

our www site: www.4QD.co.uk/serv/ than we can

print here!

Controller appears to be dead

Check the High Pot lockout (page 8) and the pot you

are using. HPLO and pot fault detector are intended

to detect faults and stop the controller from

working.

If HPLO engages, it will cause the power relay to

deactivate.

If a Pot fault is detected, it will simply prevent the

controller giving any output, but will not disengage

the relay.

Controller switches off erratically

The protection circuitry will switch the controller off

in the event of a fault: faults inside the controller are

rare and generally are not erratic: the controller

works or it fails.

Parking brake is used: if this is faulty or is drawing

too much current, the controller will switch off and

this will seem erratic.

Otherwise: if too low a pot value is used or some

other device draws current from the pot supply, a

fault will be detected.

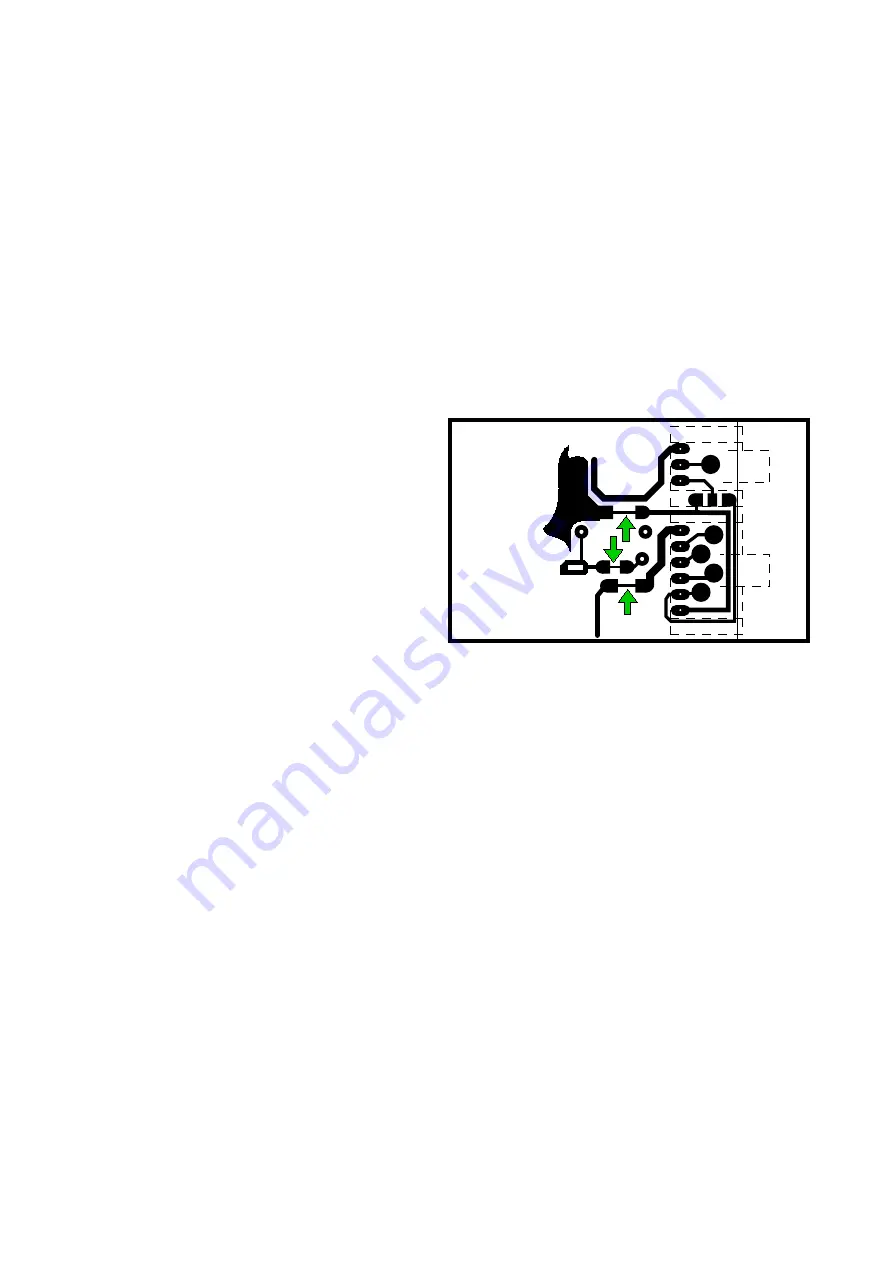

Fuse and fuse tracks

These are present to prevent major damage to the

controller is there is an external wiring fault.

There are three special sections of track which

should blow if a major fault occurs in the controls or

the brake (connected to the 6 pin and 3 pin input

connectors). They are situated beneath the input

connectors on the back of the board. They are thin

‘waists’ in the track and are is as shown arrowed in

the diagram, above. If one fuses, solder a fine piece

of wire over it - one strand from 7/0.2 cable is fine.

If you cannot cope with fixing the fuse track, should

it blow, then you should fit the fuse shown in the

‘Connections’ diagram, page 7. Use a 1 amp fuse.

Overheating

Beware of sustained overheating: the heatsink can

operate up to 95°C but not more (the overheat sensor

will operate).. The main decoupling capacitors may

get warm, but should not be allowed to remain too

hot to touch for too long.

The other limit is the soldering to the relays: the

current is limited just below that required to cause

the solder to melt!

earth track

There are few applications where regenerative

braking is deleterious and it should normally be left

engaged. However it is possible to disengage it.

When regen braking is disengaged:

1: the controller must be also switched to pre-select

reversing (section 9.08)

2: Chose a long deceleration ramp setting, as the

motor will brake only under friction.

Failure to do this will cause jerky performance and

may burn out the relays.

To deactivate regen braking, the two links shown as

RB1 and RB2 on the features diagram, page 4 must

be broken. Holes are present so removable headers

can be fitted, but these are normally not present.

17 Disabling Regen Braking