Page 36

3M

™

Straight Line Laminator Single Head Manual

|

Original Assembly and Operation Instructions

Effective: August 2022

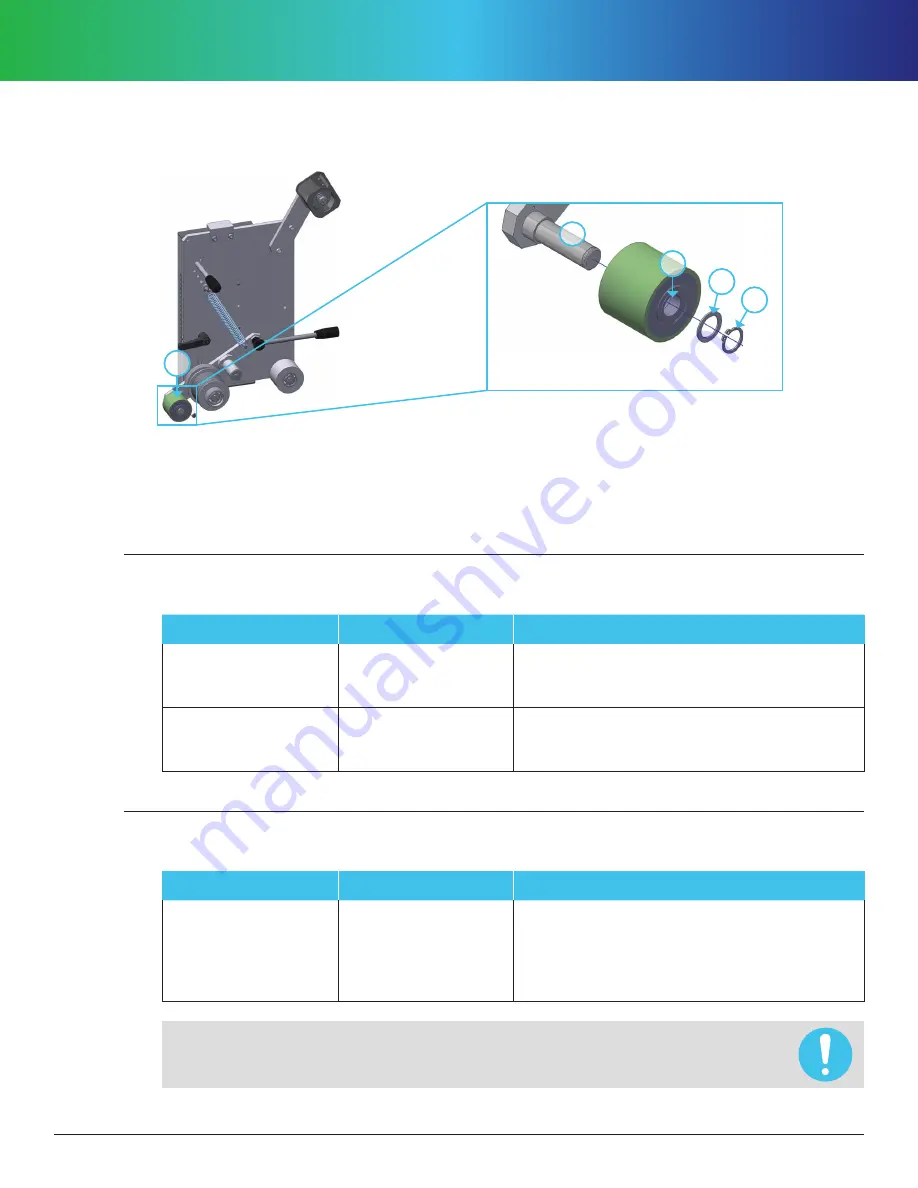

9.1.4 Maintenance and Replacement of the Application Roller

Figure 36

1 . To replace the application roller (Figure 36A) remove the retaining ring (Figure 36E) .

2 . Then you call pull the washer (Figure 36D) and the application roller (Figure 36C) off the axle of the

application roller (Figure 36B) .

3 . Assembly takes place in reverse order .

9.2 Maintenance Schedule

Assembly Group

Interval

Work to be Performed

Continuous Laminator

As required .

Over time, residues of the adhesive tape may

deposit . In case of increased wear, it may be

necessary to replace highly stressed components .

Non-stick Coated Parts

Monthly/immediately

when adhesive tape

begins to stick!

Check for damages and non-stick effect and

replace, if necessary .

9.3 Cleaning Schedule

Assembly Group

Interval

Work to be Performed

Continuous Laminator

Every 3 days .

Daily if necessary .

Cleaning of the coated deflection pulleys .

Over time, residues of the adhesive tape

may deposit . Remove moderate soiling with

FT 100, heavy soiling with GS 200 .

Please Note: No mechanical cleaning!

NOTE:

Please observe the operating instructions of the respective purchased parts as well .

A

B

C

E

D