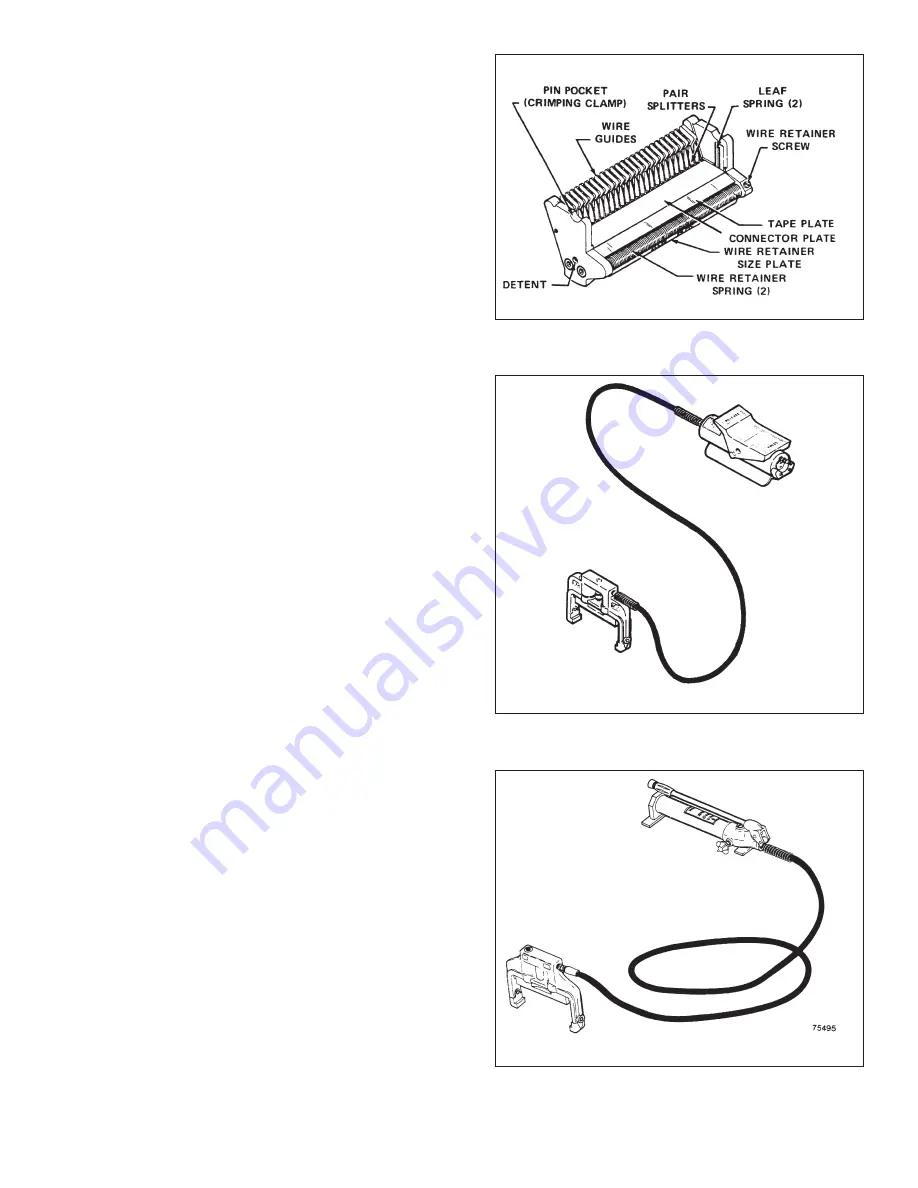

A. Splicing Head Detail (See Figure 97).

Wire guides, pair splitters, and retainer springs are coated

with an electrical insulation. Tape plate is plastic.

B. MS

2

Air/Hydraulic Crimping Unit (See Figure 98).

1. Description-Pump can be operated either by foot or

hand. An air cylinder or compressor with an output

pressure of 6.3-7.0 Kg/cm2 (90-100 Psi may be used

as source. It is recommended that this pressure be held

as close to the upper end as possible to provide a faster

crimping action.

The air/hydraulic pump is factory adjusted to a pressure cut-

off of 309 Kg/cm

2

(4400 psi) (nominal). A by-pass valve

opens when cut-off pressure is reached; crimping clamp will

hold until released.

The air supply fitting on pump is air valve Schrader Catalog

No. 645-A6. It mates with:

a. Chuck, Air Snap-On Schrader No. 5499.

b. Chuck, Clip Schrader No. 6529.

2. Bleeding Instructions (if crimping bar does not come

down)-To bleed if air-bound, place clamp lower than

pump and tilt output hose of pump up. Press pedal until

clamp resumes normal operation.

3. Connecting Hose-1.8 m X 6.4 mm (6' X 1/4") rubber

hydraulic hose (steel reinforced) Male 1 /4" - 18 NPT

fitting on each end with spring guards.

C. MS

2

4031 Hand/Hydraulic Crlmping Unit (See

Figure 99)

1. Pressure cut-off is set at factory to 309 Kg/cm

2

(4400

psi) (nominal). By-pass valve opens when cutoff

pressure is reached; crimping clamp will hold until

released.

2. Bleeding Instructions (if crimping bar does not come

down)-To bleed if air-bound, place clamp lower than

pump and tilt output hose of pump down. Actuate

handle until clamp resumes normal operation.

3. Connecting Hose-1.8 m X 6.4 mm (6' X 1/4") rubber

hydraulic hose (steel reinforced) Male 1 /4" - 18 NPT

fitting on each end with spring guards.

Figure 97.

Figure 98.

Figure 99.

Summary of Contents for MS2 4000 Series

Page 2: ......

Page 5: ... ...

Page 21: ...21 Figure 46 Figure 47 ...

Page 36: ...36 D Supply Information ...

Page 37: ...37 ...

Page 39: ...39 ...