12

4.0 USE

4.1

bEFOrE EACH USE:

Verify that the work area and Personal Fall Arrest System (PFAS) meet all criteria defined in Section

2 and that a formal Rescue Plan is in place. Inspect the Variable Davit System per the ‘

User

’ inspection points defined

on the “

Inspection and Maintenance Log

” (Table 2). If inspection reveals an unsafe or defective condition, do not use the

system. Remove the system from service, clearly mark the system “DO NOT USE”, and destroy it or contact 3M regarding

replacement.

4.2

ADJUST FOr SySTEm OFFSET:

To avoid tipping the base during use, the Variable Davit System must be adjusted to

account for offset. See Figures 9 and 10 for reference. To adjust for offset requirements:

Determine the operating offset of the Davit mast:

See Figure 9 for reference. Pin Positions (PP) are listed 1 - 4.

The Pin Positions regulate the Top Pulley (A4) and Bottom Pulley (A3) offsets. The first table within Figure 9 displays the

maximum offset (Max) and minimum offset (Min) for each pulley in all four Pin Positions. Maximum offset is determined

when the Adjustable Gusset is fully collapsed, with no visible threads. Minimum offset is determined when the Adjustable

Gusset is fully extended. Once the Pin Position is set, the second table within Figure 9 should be consulted for the

maximum load of each attachment point.

;

For use of the A1 attachment point, the distance of attachment from the Mast (Y) must be no greater than 15.0 in.

(38.0 cm).

Adjust the Davit base for the Davit mast:

See Figure 10 for reference. Once the operating offset of the Davit Mast has

been determined, the Davit Base should be adjusted to match its requirements. The Base Pin Position (BPP) of each Leg

Assembly should be matched with the Pin Position of the Davit Mast. For example, a Pin Position of 4 on the Davit Mast

should be matched with a Base Pin Position of 4 on the Davit Base.

;

After the Davit Base has been adjusted, verify that the Davit Base is level again with use of the Level Indicator. If

necessary, make height adjustments of the Adjustable Feet.

5.0 INSPECTION

5.1

INSPECTION FrEQUENCy:

The Variable Davit System must be inspected at the intervals defined in Section 1.

Inspection procedures are described in the

‘Inspection and Maintenance Log’ in Table 2.

Inspect all other components of

the Fall Protection or Rescue System per the frequencies and procedures defined in the manufacturer’s instructions.

;

In addition to the annual inspection and inspection before each use, the Variable Davit System should be inspected

at least once each week.

5.2 DEFECTS:

If inspection reveals an unsafe or defective condition, remove the Variable Davit System from service

immediately, clearly mark the system “DO NOT USE”, and destroy it or contact 3M regarding replacement. Do not attempt

to repair the Fall Arrest System.

5.3

PrODUCT LIFE:

The functional life of the Variable Davit System is determined by work conditions and maintenance. As

long as the product passes inspection criteria, it may remain in service.

6.0 MAINTENANCE, SERVICING, STORAGE

6.1 CLEANING:

Periodically clean the metal components of the Variable Davit System with a soft brush, warm water, and a

mild soap solution. Ensure parts are thoroughly rinsed with clean water.

6.2 SErVICE:

Only 3M or parties authorized in writing by 3M may make repairs to this equipment. If the

Variable Davit System has been subject to fall force or if inspection reveals an unsafe or defective condition, remove

the system from service immediately, clearly mark the system “DO NOT USE”, and destroy it or contact 3M regarding

replacement.

;

Only 3M or parties authorized in writing by 3M may make repairs to this equipment.

6.3

STOrAGE AND TrANSPOrT:

When not in use, store and transport the Variable Davit System and associated fall

protection equipment in a cool, dry, clean environment out of direct sunlight. Avoid areas where chemical vapors may

exist. Thoroughly inspect components after extended storage.

7.0 LABELS

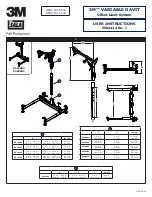

Figures 11 and 12 illustrate labels present on the Variable Davit System. Figure 11 illustrates label locations and Figure 12

displays the associated labels. Labels must be replaced if they are not present and fully legible. Information provided on each

label is as follows:

1

A) Serial Number B) Manufactured (Year/Month) C) Lot Number D) Model Number E) Length (ft.)

2

A) Warning: Available Mast Offsets (Davit Mast)

3

A) Warning: Max working load 450 lb. (205 kg); Average Arresting Force 900 lbf (4.0 kN)

4

A) Warning: Read all instructions.

5

A) Warning: Available Mast Offsets (Davit Base)

6

Directional Indicator

7

Directional Indicator

8

A) Rated to ANSI Z359.1 requirements. B) 5,000 lbf (22 kN) Maximum Arresting Force

Summary of Contents for DBI SALA Variable Davit

Page 2: ...2 2 A C B F G M J I K L H A D E C B N 3 4 B C FC C B A FC...

Page 3: ...3 5 6 A B C D E F G A B C 7 G E F D K K I B O J H D N M M L L M M 1 2...

Page 28: ......

Page 30: ......

Page 31: ......