11

3.0 INSTALLATION

3.1 PLANNING:

Plan your fall protection system prior to installation of the Variable Davit System. Account for all factors that

may affect your safety before, during and after a fall. Consider all requirements, limitations, and specifications defined in

Section 2 and Table 1.

•

Plan your work program before starting. Have the required people, equipment, and procedures available for the job.

•

Always work in teams. One person being raised or lowered and another person to pay out and reel in the line.

•

Wear appropriate protective gear including, but not limited to: a hard hat, safety glasses, protective shoes with slip

resistant soles, heavy gloves, protective clothing, or a face mask.

•

All anchor points and mounting locations must be approved by a Qualified Person.

•

All winch and SRD mounting parts and hardware must be supplied or approved by 3M Fall Protection.

•

Securely anchor the winch and SRD before use.

•

Winches and SRDs may not be mounted in the front position on lower masts or mast extensions. Rear mounting is

allowed at any point.

•

System users must use a 3M-approved Full Body Harness.

•

Use only retractable devices and energy absorbers with a maximum arrest force equal to or less than the lowest-

rated component of your system.

•

Retractable devices and energy absorbers must be installed and used in accordance with the manufacturer’s

instructions.

•

All Davit Arms, Davit Masts, and Davit Bases must be used in conjunction with other 3M-approved Davit System

components. See Table 1 for a list of approved combinations.

•

Modular components are labeled with the capacities and rating to which they were designed, tested, and

manufactured. The rating of any system is considered to be the rating of the lowest-rated component in the system.

Do not use equipment if rating labels are damaged or illegible. New labels are available from 3M Fall Protection.

•

The system should be removed from the work site when no longer needed.

3.2

INSTALLING THE VArIAbLE DAVIT SySTEm:

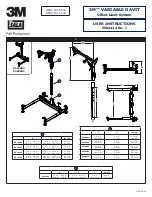

The Variable Davit System is installed in order of the Davit Base, the

Davit Mast, and the Davit Arm. See Figure 7 for reference. To install the Variable Davit System:

INSTALLING THE DAVIT bASE:

Figures 7.1 illustrates installation of the Davit Base. To install the Davit Base:

1. To get started, place each component of the Variable Davit System on the ground before you, as seen in Figure 7.1.

The Davit Arm (B), Davit Mast (O), and Davit Base should be before you. The Davit Base should include its Center

Assembly and two Leg Assemblies.

2. Remove the Locking Pin (D) from one of the Leg Assemblies. Rotate the Leg Tube (E) within the Leg Sleeve (F) from

transport position (G) to operating position (H). Reinsert the Locking Pin.

3. Insert the Leg Assembly into the Center Assembly (I). Remove the Locking Pin (K) from the Center Assembly and

reinsert it through both the Center Assembly and the Leg Sleeve once the proper width adjustments (J) have been

made.

4. Repeat Steps 2 and 3 for the second Leg Assembly.

POSITIONING THE DAVIT bASE:

Figures 7.2 illustrates stabilization and positioning of the Davit Base. To stabilize and

position the Davit Base:

1. After the desired width for the Davit Base has been set, tighten the Leg Tri-Screws (L) to stabilize the Davit Base.

2. Move the Davit Base into the established position for the work area. Adjust the Base height and level using the

Adjuster Screws (M) of the Adjustable Feet.

3. Verify that the Davit Base is level through use of the Level Indicator (N). Adjust as necessary.

INSTALLING THE DAVIT mAST AND Arm:

Figure 7.3 illustrates installation of the Davit Mast and Davit Arm. To install

the Davit Mast and Davit Arm:

1. Insert the Lower Mast (O) into the Base Sleeve (P) of the Center Assembly.

2. Verify that the Stop Dog (Q) faces the front of the Base Sleeve. The Lower Mast should rotate smoothly through its

range of rotation.

3.

Once it has been confirmed that the Lower Mast is inserted correctly, lock it into position by tightening the Base Tri-

Screw (R). Do not over-tighten since this may interfere with mast rotation.

4. Install an Upper Mast, if applicable. Only some components may be mounted with two Mast Extensions. See Table 1

for a list of mounting requirements and compatible components.

5. Install the Davit Arm (S). Ensure that the Locating Key (T) of the Davit Mast completely engages the Key-Way Slot

(U) of the Davit Arm.

6. To avoid tipping the Variable Davit System during use, the system must be adjusted to account for offset. Failing

to adequately account for offset could result in serious injury or death. See Section 4.2 for calculation of offset and

further information.

Summary of Contents for DBI SALA Variable Davit

Page 2: ...2 2 A C B F G M J I K L H A D E C B N 3 4 B C FC C B A FC...

Page 3: ...3 5 6 A B C D E F G A B C 7 G E F D K K I B O J H D N M M L L M M 1 2...

Page 28: ......

Page 30: ......

Page 31: ......