9

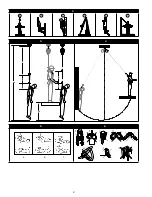

3.0 INSTALLATION AND USE

3.1

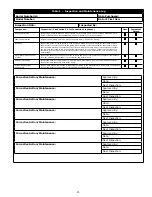

BEFORE EACH USE

of this equipment inspect it according to the

“Inspection and Maintenance Log” (Table 1)

.

3.2 PLAN

your system before use. Consider all factors that will affect your safety during use of this equipment. The following

list gives important points to consider when planning your system:

• Anchorage:

Select an anchorage capable of sustaining the Static Load requirements of the intended fall protection

application (see Section 1.1). The anchorage location should address Free Fall, Fall Clearance, Swing Fall, and

Environmental limitations described in Section 1.4.

• Sharp

Edges:

Avoid working where system components may be in contact with, or abrade against, unprotected

sharp edges.

• After A Fall:

Components which have been subjected to the forces of arresting a fall must be removed from service

and destroyed.

• Rescue:

The employer must have a rescue plan when using this equipment. The employer must have the ability to

perform a rescue quickly and safely.

• Rescue

Harness:

Rescue Harnesses are intended to be worn during normal work activities. Before using rescue

attachment elements for the

fi

rst time, the user should carry out a suspension test in safe conditions to ensure the

harness is sized and

fi

tted for optimal comfort during suspension.

3.3 ANCHORAGE

REQUIREMENTS:

The Riggersmate Hauling Kits should be attached to a suitable anchorage or anchorage

connector capable of supporting the required loads. As per AS/NZS 5532: 2013 the anchorage connector should be rated

to a minimum of 12kN for single person use and 18kN for 2 person use.

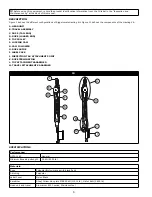

3.4 INSTALLATION

REQUIREMENTS:

1. Attach the Hauling Kit to a suitable anchorage connector as per section 3.3, using the connector provided

on the head unit.

2. The travel assembly end of the device can then be attached to the load using the connector provided.

3.5 RAISING:

1. Raise a load by pulling the tail end of the rope.

2. Whilst the load is being raised, the locking cam will engaged and disengaged once every revolution of the

top pulley, making a clicking sound.

3. Continue pulling the tail end of the rope until the load reaches the required position.

4. Slow release the tail end of the rope. If the rope tail tries to pull back through the device, raise the load

another 50mm to engage the locking cam.

5. The travel assembly should never be raise to interfere with the rope termination.

3.6 LOWERING:

1. To lower the load, pull on the tail end of the rope until the locking cam disengages.

2. Slowly allow the tail end of the rope be pulley back through the device by the raise load.

3. To stop lowering, pull on the tail end of the rope and raise the load 50mm to engage to locking cam.

3.7 MAKING

CONNECTIONS:

When using a hook to connect to an anchorage or when coupling components of the system

together, ensure roll-out cannot occur. Roll-out occurs when interference between the hook and mating connector causes

the hook gate to unintentionally open and release. Self-locking snap hooks and carabiners should be used to reduce the

possibility of roll-out. Do not use hooks or connectors that will not completely close over the attachment object. See

subsystem manufacturer’s instructions for more information on making connections.

3.8 OVER-SPEED

LOCK:

All Riggersmate Hauling Kits are equipped with an internal over-speed lock. If at any point during

operation the load becomes uncontrolled or the tail end of the rope released, this feature will automatically lock and

prevent the load from falling to the ground. If the over-speed lock is activated, follow the lowering procedure, section

3.6, to continue operation. As soon as possible after an over-speed lock the unit shall be inspected as per section 5 of this

manual. Do not continue to use this product after an over-speed lock unless completing a rescue.