3D SYSTEMS, INC.

75-D059 REV_A

19

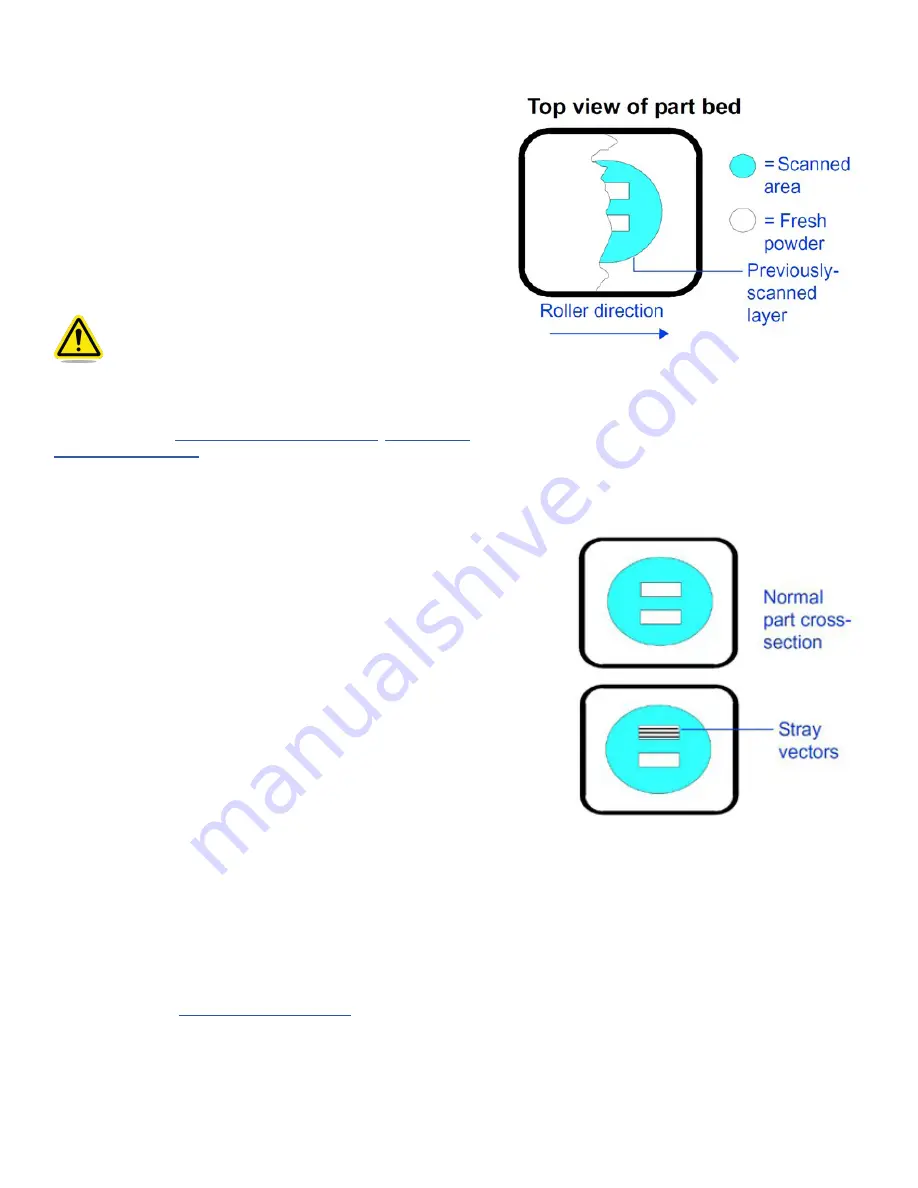

SHORT FEEDS

Description: The roller does not deliver enough material to cover the

previous layer .

Theory of Cause

: Short feeds can occur when the feed amount is

too short; the part cross-section changes from small to large.

Visual Signs

: Part bed not completely covered after a layer is

spread . Part bed cracking may also appear .

Consequences

: The part will usually be weak, may delaminate

at layers where short feeds occurred, and may have surface

imperfections .

Corrective Action: Increase the Feed Amount parameters in the Print

Parameters Profile or use the Prime Cycle button.

Caution! Exercise care when varying the Feed Amount

parameters. The feed material during a print is

considerably cooler than the material in the print

bed. Using a feed that is too large can cause excessive

cooling of the part as the material is delivered, which

will lead to curl during printing.

You also may want to use the Prime Cycle button to cover the part .

Related Problems

“Melting, Print Bed” on page 17

STRAY VECTORS

Description:

A line occurs between two fill areas where it should

not be .

Theory of Cause:

The STL file is incorrect. The vertices of the facet

do not meet . This is not material related .

Visual Signs:

The laser scans an area in the cross-section that it

should not scan . This usually results in one or more lines connecting

the fill areas.

Consequences:

Stray vectors make it more difficult to clean and

break out parts .

Corrective Action:

Prior to beginning the print, check the STL file

for stray vectors using the Preview tab in Build Setup . Rotate the

orientation of the part slightly . Preview the part again . Verify the

original CAD file.

If the original CAD file is correct

, the STL file has probably been

corrupted and you must make a new one . Repeat the process to

save the file into the STL format: copy the new file to the SLS system

computer, set up a build packet with the new file, and preview it

again . If the problem recurs, contact 3D Systems customer support .

If the original CAD file is incorrect

, make the necessary changes to the

CAD file, save the file into the STL file format, and copy the new file

onto the SLS system computer. With the new file, set up a new build

packet and try printing the part again .

If the stray vectors are not too severe, file or cut them off. If the

problem is too severe, you may need to terminate the print; trying

to remove severe stray vectors from the part during breakout may

cause the part to break .

Related Problems: