ES3, ES4 & ES6 Instructions. Issue: No. 2

Page 13

February / 2012

nOTE!

When used to supply a mixer tap a flow restrictor may be required on the

cold supply to the tap to balance the flows.

For further information see the Fault Finding table, page 14.

When the unit has been commissioned, explain the functions of the heater to the

end user and ensure they know how to use the appliance.

Hand over these instructions for the user to keep.

Maintenance and cleaning

nOTE!

Maintenance work must only be carried out by a competent person familiar

with instantaneous water heaters.

Plastic surfaces and sanitary fittings should only be wiped with a damp cloth.

Never use abrasive cleaning agents or solvents.

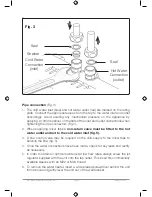

Outlet fittings (jet regulator Fig. 5) should be unscrewed from the tap nozzle and

cleaned at regular intervals.

•

Rinse the regulator with water and brush off the debris. For difficult to remove

deposits, soak in white vinegar (or a proprietary scale cleaner)

for a few minutes

and scrub with a toothbrush.

•

If any parts are cracked or broken, replace them. If the washer has hardened,

it should be replaced.

•

With the debris cleaned out, screw the regulator back into the tap.

Hand tightening should be adequate.

The electrical and plumbing components should be inspected regularly by

a competent person to ensure proper functioning and operational safety.

Water quality should be considered when determining the frequency of inspection.

Each time the appliance is emptied (e.g. due to work on the plumbing

system, if there is a risk of freezing or in case of maintenance), the appliance

must be purged by opening and closing the hot water tap until all air has

been eliminated from the water heater and no more air emerges before

re-connecting to the electrical supply.

Содержание InLine ES3

Страница 2: ...Inside Back Cover Inside Front Cover...