INSTALLATION AND OPERATING INSTRUCTIONS:

Motor spindle, HF150-003 series

Zimmer GmbH

•

Im Salmenkopf 5

•

77866 Rheinau, Germany

•

+49 7844 9138 0

•

+49 7844 9138 80

•

www.zimmer-group.com

30

EN / 2020-10-22

DDOC00746 / -

11.4 Preparing for operation

11.4.1 Machining tools

CAUTION:

The use of an unsuitable tool holder will cause damage to the motor spindle

Ö

For high machining performance, use a hydraulic tool holder/ shrink chuck.

Ö

For high machining performance, use tools with a firmly attached hollow taper shank.

For hydrostatic tool clamp equipment, e.g. hydraulic tool holders, DIN EN 848-3 must be observed.

Hydraulic tool holders feature an additional mechanical device to prevent the tool from being released as the result of

leakage in the hydrostatic system.

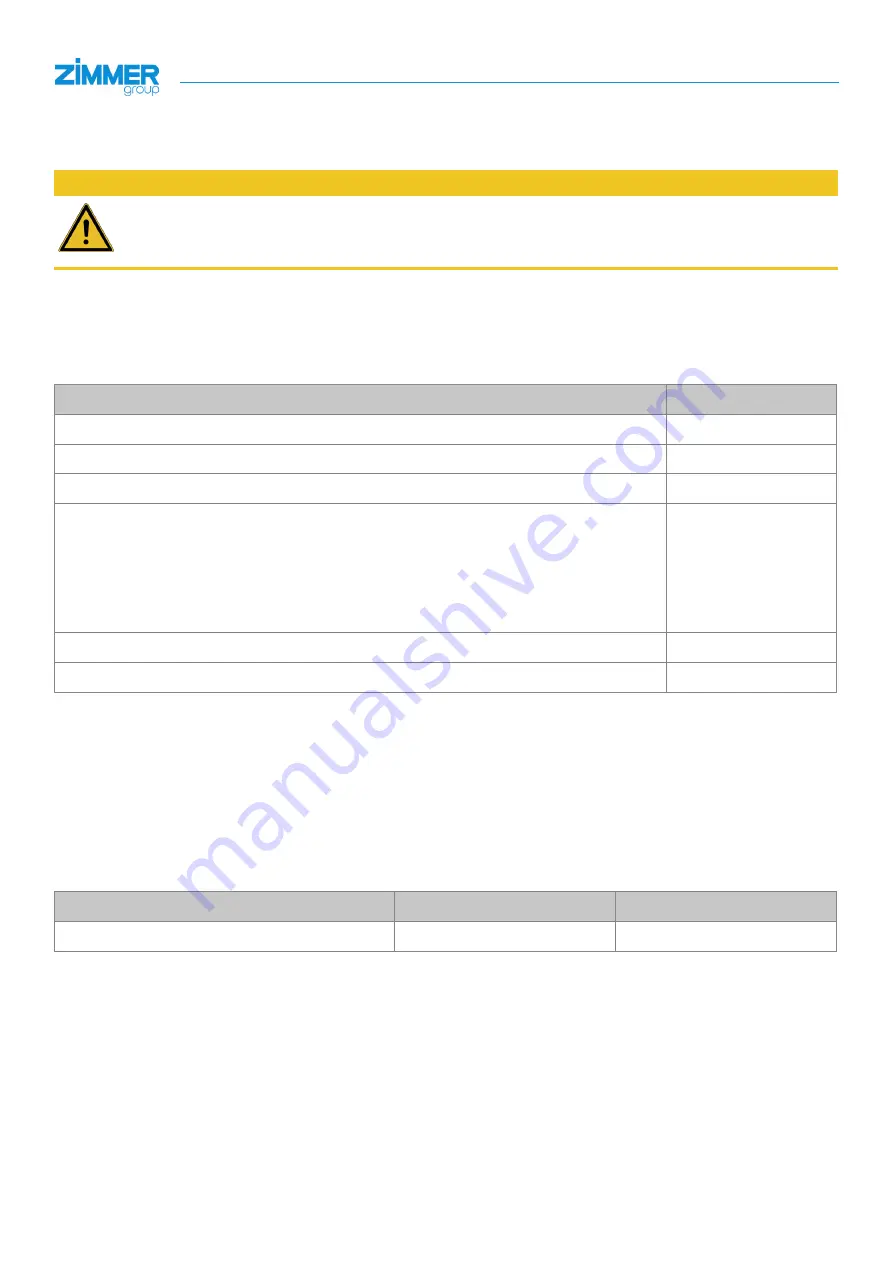

11.4.2 Tool data

Speed range

0 to 24,000 rpm

Maximum tool diameter

180 mm

Maximum tool weight

6 kg

Maximum tool length (including holder)

280 mm

Balancing quality:

►

Tool fixture with tool dynamically balanced according to ISO 1940

G2.5

►

Will shorten the life cycle

G2.5 to G6.3

►

A balance quality above G6.3 according to DIN ISO 1940 will shorten the life cycle signifi

-

cantly and must not be used!

Above G6.3

Direction of rotation

left/right

Maximum concentricity error

0.02 mm

11.4.3 Feed rate

The feed rate must be adjusted to the characteristics of the workpiece, the type of processing, the speed and the tool.

►

Determine the correct feed rate in consultation with the tool manufacturer.

►

Perform your own tests and document the results.

►

Begin with a reduced feed rate.

11.4.4 Angular acceleration

The maximum programmable angular acceleration must not be exceeded.

Properties

Units

Values

Maximum angular acceleration α

rad / sec

2

1000

11.5 Removing from operation

►

Exit the processing program.

►

Remove the tool from the motor spindle.

►

Perform the tasks for decommissioning the base machine.

►

Switch off the main switch.