3.1 GENERAL MAINTENANCE INFORMATION

While the

A.T.S.

1200 Tourniquet has been designed and

manufactured to high industry standards, it is recommended

that regular inspection and calibration be performed to

ensure continual safe and effective operation. This section

contains information to assist in the effort as well as serve as

a guide to expediting unscheduled maintenance.

3.2 ACCESS TO PARTS

CAUTION:

Be sure that the unit is set to STANDBY and

the power plug is unplugged before disassembly. Many of

the parts on the control board are static sensitive. Take

precaution when servicing the board.

To gain access to all internal parts, remove:

a)

Rear – 5 screws

b)

Rear – 2 large pole clamp screws

c)

Bottom – 4 foot pad screws

See Illustration 4 through 8 in the back of the manual.

When opening, take care not to damage any of the wire

harnesses or pneumatic tubing. The control board is attached

to the front housing therefore the harnesses and tubing will

need to be disconnected for full disassembly. Follow the

table below to reassemble.

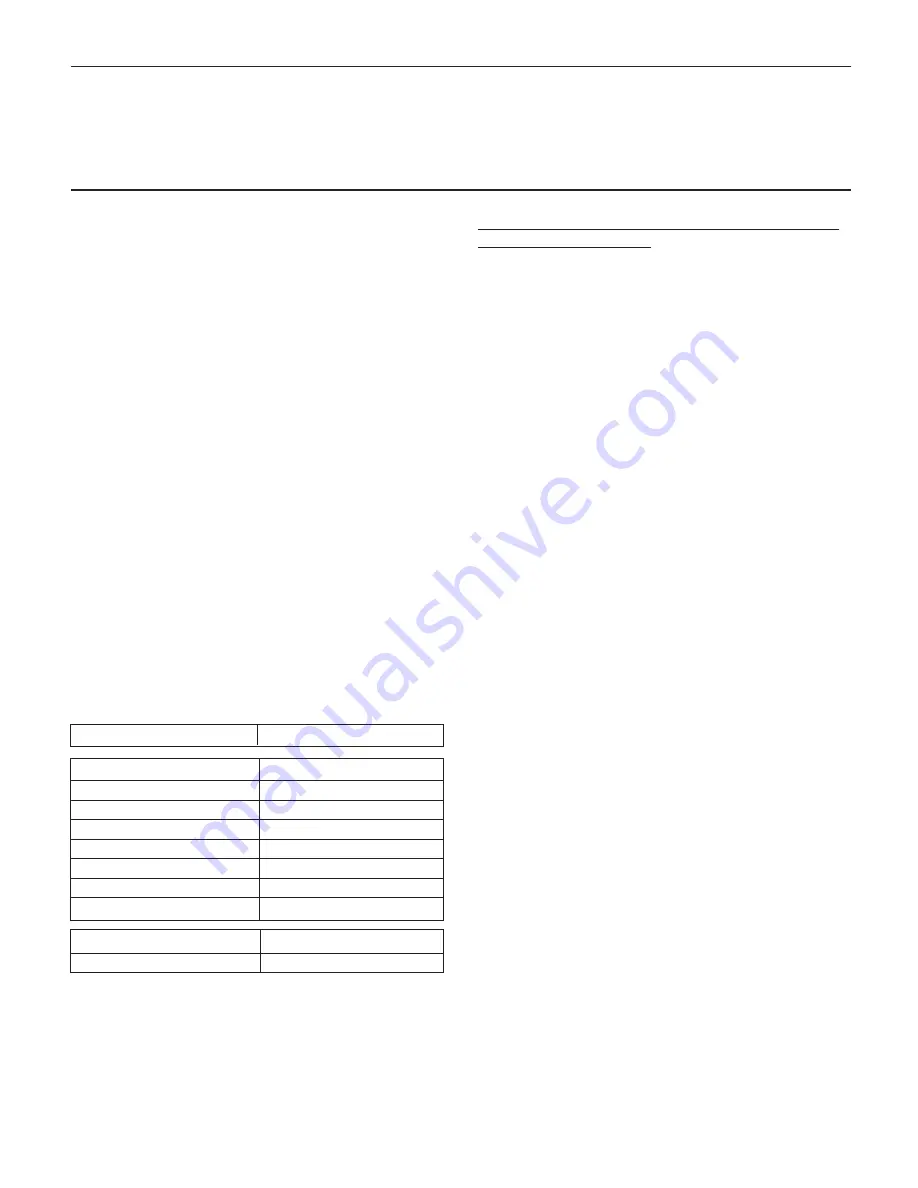

Table 3.1 Board Plug Designators

Component

Board Plug Location

AC Mains

P1

Overpressure Switch

P2

Speaker

P3

Pneumatic Pump

P5

Valve Harness

P6

Backup Battery

P7

Membrane Panel

P8

Factory Test Port

P9

Main Cuff Port Tube

U17

Second Cuff Port Tube

U21

To reduce the risk of damage, the tubing should be

disconnected at the plastic tee fitting and not the transducer.

NOTE: Failure to plug the electrical or pneumatic

components into the correct associated receptacle can

result in damage to the control board.

When reassembling the unit, be extremely careful not to

pinch any wiring or tubing.

3.3 PERIODIC MAINTENANCE

Test and inspect as per this section at minimum every six

months.

1.

Cleaning

The exterior of the unit may be cleaned with a cloth that

has been dampened (not dripping) with a mild detergent.

The interior of the unit may be vacuumed or blown out

as required. The exterior of the cuff hose may be cleaned

using a mild detergent solution or alcohol. The interior

of the cuff hoses should not be cleaned. Tourniquet cuffs

should be cleaned in accordance with their cuff package

inset instructions.

2.

Inspection

The unit should be inspected at regular intervals. It is

recommended that a qualified technician perform a

visual inspection at least once every six months.

Inspection points are:

a)

Obvious internal or external damage.

b)

Condition of the power cord.

c)

Condition of the power cord-retaining clip.

d)

Tightness of pneumatic fittings.

e)

Condition of internal tubing.

f)

Accumulation of dust or dirt within the unit.

g)

Mating integrity of internal connectors.

h)

Security of the EPROM and safety processor.

See Illustration 9 for location.

i)

Integrity of the pump.

j)

Security of circuit board.

k)

Security of the membrane panel.

3.

Functional and Calibration Checks

It is recommended that the functional and calibration

checks described in Section 2.4 are performed at least

once every three months.

3.4 CALIBRATION

Calibration should be performed every six months, or

after any unscheduled maintenance.

Calibration of the

A.T.S.

1200 Tourniquet allows the

output signal from the pressure transducer to be compared

against a calibrated pressure source. The difference between

the known pressure and the pressure measured by the

transducers is recorded at each of four set points (0 mm Hg,

50 mm Hg, 250 mm Hg, and 475 mm Hg). These four

calibration factors are used to correct the signal from the

pressure transducers during normal operation. The calibration

factors and a checksum are stored in non-volatile memory.

15

MAINTENANCE

SECTION 3.0

A.T.S. 1200 TOURNIQUET SYSTEM

Содержание A.T.S. 1200

Страница 1: ...Operator Service Manual A T S 1200 TOURNIQUET SYSTEM REF 60 1200 101 00...

Страница 26: ...R Power Cord S Cord Retaining Clip T Factory Test Port U Pole Clamp V Mains Fuse Block 24 2...

Страница 30: ...28 9 Control Board Layout...

Страница 32: ...30 10...

Страница 33: ...SCHEMATICS...