RPC-2 REVERSE PULSE DUST COLLECTOR

Page 8

© 2012 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 22788

6.0 SERVICE

MAINTENANCE

WARNING

All maintenance must be done with the

electrical power locked-out and tagged-out, and

the compressed air supply line bled, locked-out

and tagged-out. Failure to do so could result in

death or serious injury from electrical shock,

unintentional actuation of a component, or from

the venting of trapped compressed air.

6.1

Replacing Filter Cartridges

WARNING

Failure to wear properly fitted and maintained,

NIOSH approved respirator and eye protection

when servicing dust laden areas of the dust

collector could result in serious eye irritation

and lung disease or death. Toxicity and health

risk vary with type of media, and dust

generated by blasting. Identify all material that

is being removed by blasting, and obtain a

Materials Safety Data Sheet for the blast media.

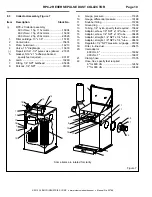

6.1.1

Empty the dust drawer, and return the drawer to

its position.

6.1.2

Open the top access door.

6.1.3

Remove the nuts securing the cartridge hold-

down plates.

6.1.4

Remove the hold-down plates and venturi tubes.

6.1.5

Remove cartridges from the top. A small amount

of force may be necessary to loosen the seal of the

cartridge gasket.

6.1.6

When cartridges are removed, clean the inside

of the collector to remove loose or hardened dust,

particularly from the cartridge sealing surface, and the

clean side (top side) of the cartridge sheet.

6.1.7

Install new cartridges; center each cartridge,

install venturi tube, and secure with hold-down plates.

6.1.8

Inspect the access door gasket, replace if worn

or damaged. Close the access door and secure.

6.1.9

Reset timer OFF time to 40 seconds.

6.1.10

Reset pressure to 70 psi.

6.1.11

Season cartridges per Section 6.2.

6.2 Seasoning

Cartridges

6.2.1

New cartridges must be seasoned. Cartridges

are seasoned by letting a dust layer develop on the

outside surface of the filter media. The dust layer protects

the filter cartridge, and enhances the filtering efficiency.

6.2.2

Operate

the

collector

without pulsing (sequence

switch off) until the differential pressure gauge reads four

inches (4" w. c.).

6.2.3

After the differential pressure is reached, set the

timer OFF time to 40 seconds, and set the pulse pressure

at 70 psi.

6.2.4

Turn the sequence switch ON to start the pulse

cycle. See Section 4.2.

7.0 TROUBLESHOOTING

WARNING

Shut down the collector immediately if dust is

emitting from the exhauster. Check to make

sure that cartridges are correctly seated and

not worn or damaged. Prolonged breathing of

abrasive dust and blasting by-product dust

could result in serious lung disease or death.

Short term ingestion of toxic dust such as red

lead, poses an immediate danger to health.

Identify all materials that are to be removed by

blasting, and obtain a Materials Safety Data

Sheet for the blast media

.

7.1

Collector Not Pulsing

7.1.1

Check the manifold pressure gauge. If the

reading is low, check the regulator adjustment, and

compressed air supply, look for a closed supply valve.

7.1.2

Check to make sure the sequence switch is not

turned off.

7.1.3

Check the fuse in the sequence control panel.

Replace as necessary.