RPC-2 REVERSE PULSE DUST COLLECTOR

Page 7

© 2012 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 22788

inches the fluid travels down the other column. Refer to

the example in Figure 5.

4.4.10

After the readings are taken, replace the needle

protector. Close the manometer valves and store the

manometer in the original container in a clean area.

Note: If the manometer installation is permanent, the

manometer may remain on the reclaimer body after the

valves are closed.

Figure 5

5.0 PREVENTIVE

MAINTENANCE

WARNING

Always wear a properly fitted and maintained,

NIOSH approved respirator and eye protection

when emptying the dust drawer. Failure to do

so could result in respiratory disease or serious

respiratory and eye irritation. Toxicity and

health risk vary with type of media, and dust

generated by blasting. Identify all material that

is being removed by blasting, and obtain a

Materials Safety Data Sheet for the blast media.

5.1 Daily

5.1.1

With the exhauster turned off, empty the dust

drawer. Heavily contaminated parts or friable media may

require the drawer be emptied more often. Never allow

the drawer to become more than a quarter full.

5.1.2

Check the exhaust air during a pulse cycle. If

dust is emitting from the exhauster, cartridges are

leaking or damaged. Check immediately.

5.1.3

With the exhauster turned on, check the

differential pressure gauge. If reading is high (greater

than 4" above initial reading), adjust pulse pressure

and/or sequence per Section 4.1 and 4.2.

5.2 Weekly

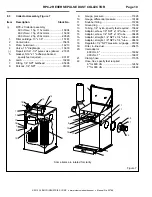

5.2.1

With the exhauster turned off, check the in-line

dust filter dust accumulation. The filter is located on the

side of the collector. See Figure 6.

Figure

6

Cartridge Sheet

Clean side of

cartridge sheet

Dust side of

cartridge sheet

Snubber Fitting

Low pressure line to top

side of cartridge sheet

High pressure line to

bottom side of cartridge

sheet

Dust Filter

The manometer must be vertical when

taking pressure readings.

With the exhauster OFF,

slide the rule to align the

zero with the fluid level.

In the example shown, fluid traveled up

the right column 1-3/4 inch,

and down the left column 1-3/4 inch.

Static pressure is determined by adding

the columns together. In the example,

the static pressure is 3-1/2 inches.

To obtain the pressure reading: With

the exhauster ON, add the number of

inches the fluid travels up the column,

and the number of inches the fluid

travels down the other column. The total

is the static pressure reading.