21

GB

Device for automatic control of electric pumps in water systems:

Electronic pressure switch

ZD 15

/ ZD 20

•

• Replaces the traditional system with expansion tank

• Turns on or off the pump depending on the opening or closing of the sampling points

• Keeps the pressure constant during removal

• Switches off the pump if there is a lack of water and offers dry-running protection

• Prevents pressure shock effects

• Requires no maintenance

TECHNISCHE DATEN

protection class

device

max. operating pressure

max. operating temperature

65 °C

Voltage, single-phase

permissible voltage fluctuations

frequency

maximum current

maximum power

external thread

Non-adjustable standard switch-on pressure between min.1.5 bar and max. 2. bar.

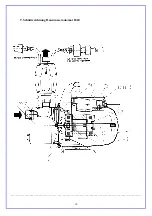

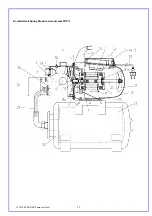

INSTALLATION (Fig. 1 and 2)

Attention: Before installing, make sure that the technical characteristics of the device, the Pump and the system are compatible with

each other.

ZD15:

The maximum pressure generated by the pump must be at least 3.5 bar (0.35 MPa) and at most 8 bar (0,8 MPa).

ZD20: The maximum pressure generated by the pump must be at least 3.0 bar (0.3 MPa) and at most 10 bar (1 MPa).

The water column between the appliance and the highest extraction point must not exceed 15 m.

The pump either locks up or does not shut off if the pressure of the pump does not reach the values indicated above.

The pump will start, but will not turn on or it will not turn off when the water column height exceeds the specified values. To eliminate

this malfunction, install the unit at a higher location.

The device can either be installed directly on the pump or between it and the first sampling point (Fig. 1). Install a pressure reducer

between the pump and the unit if the inlet pressure on the unit exceeds 8 bar (

ZD15

)

, 10 bar (ZD20)

. There must be no outlet

between the pump and the unit (Fig. 1). The appliance must be installed with the arrows indicating the direction of flow pointing

upwards (Fig. 1 / A). It is recommended to install a ball valve and a pressure gauge at the outlet of the unit to check the functioning of

the pump and the unit while it is disconnected from the unit through the valve and to use the pressure gauge to determine the

pump's actual head , The output of the unit should be connected to the system by a flexible hose (Fig. 1 / B). Before using the device,

make sure that the pump is properly vented.

POWER CONNECTION

ZD 15

(Fig. 4)

The electrical connection must be made by qualified personnel in accordance with applicable legislation. The device must always be

preceded by an all-pole switch with a contact distance of at least 3 mm. Single-phase pumps (230 V) with a motor power of up to 1.1

kW (1,5 HP) (Fig. 4 / A) can be connected directly to the unit, while single-phase pumps with a capacity of more than 1.1 kW (1,5 HP)

(Fig. 4 / B) must be connected to the device via a contactor. Check the mains voltage and the data indicated on the nameplate of the

pump motor.

230V

+/-10%

50-60 Hz

16 (6) A

1,1 kW (1,5 HP)

IP 55

ZD 15

8 bar (0,8 MPa)

G1" AG

230V

+/-10%

50-60 Hz

30 (16) A

2,2 kW (3 HP)

IP 65

ZD 20

10 bar (1 MPa)

65 °C

G11/4" AG

ZD15

ZD20

ZD15

ZD20

•

Run the power supply as shown in the diagrams in Fig. 4.

•

Use HOS or H07 cables with a cross-section of 3x1 mm².

•

Make sure that the device is connected to the grounding system.