86 / 96

CAYMAN

Version 01 - Revision 00

09/05/2017

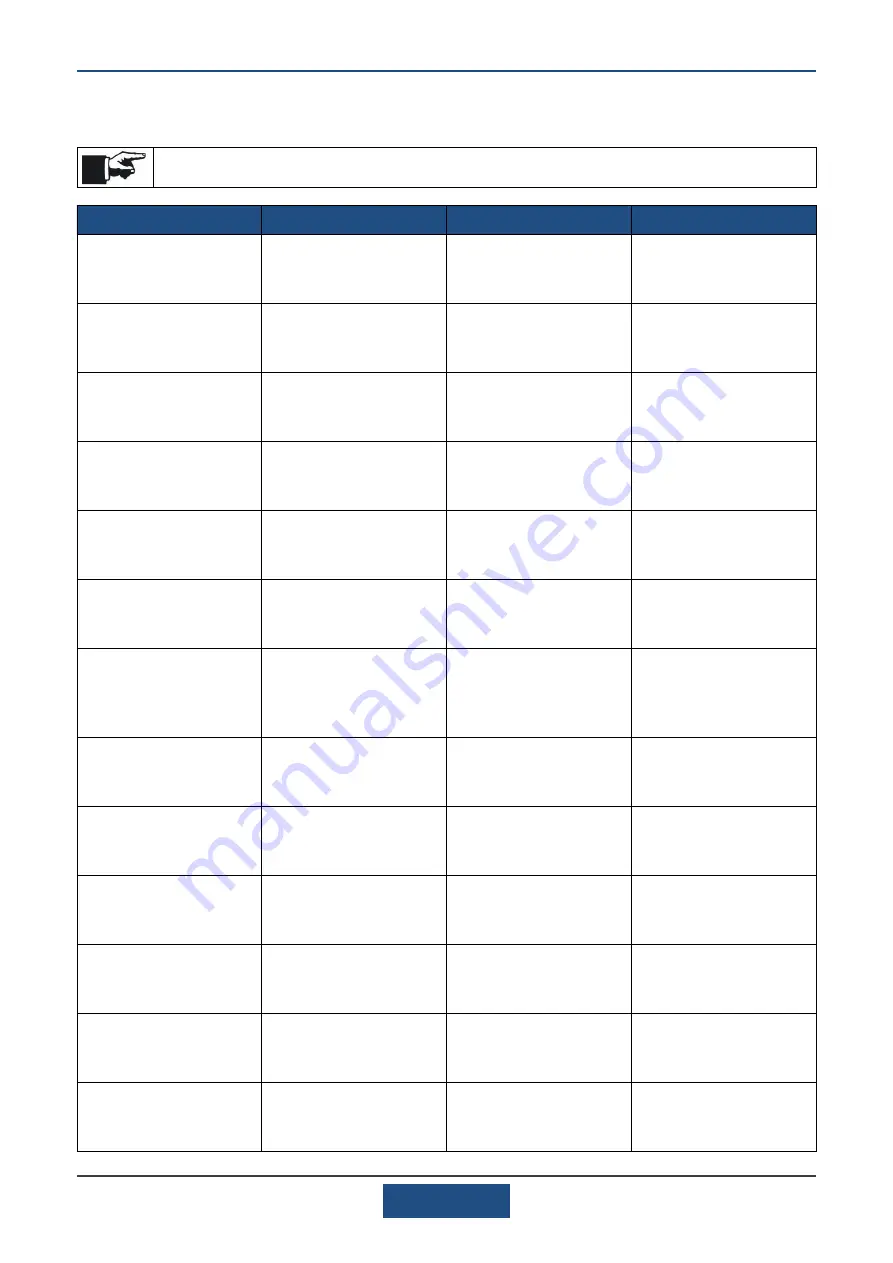

7.3

suMMarIsEd tablE of MaINtENaNCE frEquENCy

To correctly and safely use the attachment, the maintenance operations listed in the table below must be

carried out according to the specified frequency�

The maintenance work is listed in the table in descending order of frequency, considering 8

hours of work of the attachment, 5 days a week�

Components

type of operation

frequency

reference

Attachment

Visual check of the struc-

ture

Daily

Attachment

Checking the hydraulic

system

Daily

Rotating head

Checking the hydrau-

lic cylinder shaft output

area

Daily

Rotating head

Swivel hydraulic coupling

visual check

Daily

Shears

Making sure the bla-

de screws and bolts are

tightened properly

Daily

Shears

Checking the blade and

upper jaw cutting profile

radius

Daily

Shears

Checking the clearance

between the main upper

jaw blades and the main

jaw blades

Daily

Shears

Checking the clearance

between the upper jaw

and the razor blade

Daily

Shears

Greasing the central pin

Every 8 hours of opera-

tion

Rotating head

Greasing the hydraulic

cylinder front pin

Every 8 hours of opera-

tion

Rotating head

Greasing the hydraulic

cylinder rear pin

Every 8 hours of opera-

tion

Shears

Greasing the clutches

Every 8 hours of opera-

tion

Shears

Checking the correct

tightening of clutch

screws

Every 16 hours of opera-

tion

Содержание CAYMAN FCE II Series

Страница 2: ......

Страница 6: ...6 96 CAYMAN Version 01 Revision 00 09 05 2017...

Страница 38: ...38 96 CAYMAN Version 01 Revision 00 09 05 2017 7 1 2 4 8 5 3 6 Fig 10 Information and warnings applied...

Страница 94: ...94 96 CAYMAN Version 01 Revision 00 09 05 2017...

Страница 95: ......