18

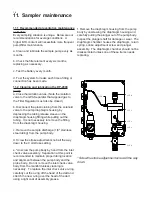

11.1 Recommended preventative maintenance

schedule

Every sampling situation is unique. Below are our

recommendations for average conditions. A

higher BTU content will necessitate more frequent

pump/filter maintenance.

a. Clean and lubricate the sample pump every six

months.

b. Check the filter element every six months,

replacing as necessary.

c. Test the battery every month.

d. Test the system for leaks each time a fitting or

connection has been made.

11.2 Cleaning and lubricating the DP-2000

pump

a. Close the isolation valves. (Note the isolation

valve to the GPA Separator that supplied gas to

the Filter Regulator must also be closed)

b. Disconnect the plastic tubing from the solenoid

valve to the pump diaphragm housing by

depressing the tubing release sleeve on the

diaphragm housing fitting while pulling out the

tubing. It is not necessary to remove the fitting

from the diaphragm housing.

c. Remove the sample discharge (1/8" stainless

steel tubing) from the pump body.

d. Screw the stroke adjustment knob all the way

down to the 0 cc/stroke setting.

e. *Unscrew the pump body by hand from the inlet

check valve assembly. Separation at this point is

recommended to maintain proper tubing location

and alignment between the pump body and the

probe body. Do not remove the inlet check valve

body from the manifold unless cleaning is

necessary. To replace the inlet check valve o-ring,

carefully cut the o-ring off the head of the dart and

stretch the new o-ring over the head of the dart

using a light coat of assembly grease.

f. Remove the diaphragm housing from the pump

body by unscrewing the diaphragm housing and

carefully pulling the plunger out of the pump body.

Inspect the plunger shaft for damage or wear. The

diaphragm chamber houses the diaphragm, return

spring, stroke adjustment screw and plunger

assembly. The diaphragm chamber should not be

disassembled unless one of these items needs

replacing.

*Screw the stroke adjustment screw all the way

down.

11. Sampler maintenance

11.2 a

11.2 c

11.2 e

11.2 f

11.2 d

11.2 b

Содержание DP-2010RX

Страница 1: ...DynaPak GasSampler S Y S T E M S U P P O R T M A N U A L DP 2010RX...

Страница 2: ...DynaPak2010RX SystemSupport Manual Version 06042001 ATEX Rev...

Страница 25: ...26 Diagram 1 DP 2000 pump assembled...

Страница 27: ...28 Diagram 3 YZ filter regulator assembled...

Страница 35: ...36 Notes...