YORK INTERNATIONAL

72

Application Data

UNIT LOCATION

The YCAL chillers are designed for outdoor installation.

When selecting a site for installation, be guided by the

following conditions:

1. For outdoor locations of the unit, select a place

having an adequate supply of fresh air for the con-

denser.

2. Avoid locations beneath windows or between

structures where normal operating sounds may be

objectionable.

3. Installation sites may be either on a roof, or at ground

level. (See FOUNDATION.)

4. The condenser fans are the propeller-type, and

are not recommended for use with duct work in the

condenser air stream.

5. When it is desirable to surround the unit(s), it is

recommended that the screening be able to pass

the required chiller CFM without exceeding 0.1” of

water external static pressure.

6. Protection against corrosive environments is avail-

able by supplying the units with either copper fin,

cured epoxy-dipped, or epoxy-coated fins on the

condenser coils. The epoxy-dipped or epoxy-coated

coils should be offered with any units being installed

at the seashore or where salt spray may hit the

unit.

In installations where winter operation is intended and

snow accumulations are expected, additional height

must be provided to ensure normal condenser air

flow.

Recommended clearances for units are given in DI-

MENSIONS. When the available space is less, the

unit(s) must be equipped with the discharge pressure

transducer option to permit high pressure unloading in

the event that air recirculation were to occur.

FOUNDATION

The unit should be mounted on a flat and level founda-

tion, ground or roof, capable of supporting the entire

operating weight of the equipment. Operating weights

are given in the PHYSICAL DATA tables.

ROOF LOCATIONS –

Choose a spot with adequate

structural strength to safely support the entire weight

of the unit and service personnel. Care must be taken

not to damage the roof during installation. If the roof is

“bonded”, consult the building contractor or architect

for special installation requirements. Roof installations

should incorporate the use of spring-type isolators to

minimize the transmission of vibration into the building

structure.

GROUND LEVEL INSTALLATIONS –

It is important that

the units be installed on a substantial base that will not

settle, causing strain on the liquid lines and resulting in

possible leaks. A one-piece concrete slab with footers

extending below the frost line is highly recommended.

Additionally, the slab should not be tied to the main

building foundation, as noises will telegraph.

Mounting holes (11/16” diameter) are provided in the

steel channel for bolting the unit to its foundation. See

DIMENSIONS.

For ground level installations, precautions should be

taken to protect the unit from tampering by or injury

to unauthorized persons. Screws on access panels

will prevent casual tampering; however, further safety

precautions, such as unit enclosure options, a fenced-in

enclosure, or locking devices on the panels may be ad-

visable. Check local authorities for safety regulations.

CHILLED LIQUID PIPING

The chilled liquid piping system should be laid out so

that the circulating pump discharges into the cooler.

The inlet and outlet cooler liquid connections are given

in DIMENSIONS.

Hand stop valves are recommended for use in all lines

to facilitate servicing. Drain connections should be

provided at all low points to permit complete drainage

of the cooler and system piping. Additionally, a strainer

(40 mesh) is recommended for use on the INLET line

to the cooler.

Pressure gauge connections are recommended for

installation in the inlet and outlet water lines. Gauges

are not furnished with the unit and are to be furnished

by other suppliers.

The chilled liquid lines that are exposed to outdoor am-

bients should be wrapped with a supplemental heater

cable and covered with insulation. As an alternative,

ethylene glycol should be added to protect against

freezeup during low ambient periods.

A flow switch is available as an accessory on all units.

The flow switch (or its equivalent) must be installed in

the leaving water piping of the cooler and must not be

Содержание YCAL0041

Страница 10: ...YORK INTERNATIONAL 10 This page intentionally left blank...

Страница 61: ...YORK INTERNATIONAL 61 FORM 150 64 EG1 INTENTIONALLY LEFT BLANK...

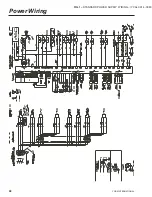

Страница 68: ...YORK INTERNATIONAL 68 Power Wiring FIG 1 STANDARD POWER SUPPLY WIRING YCAL 0014 0080...

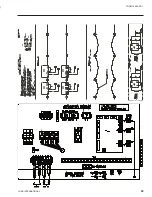

Страница 69: ...YORK INTERNATIONAL 69 FORM 150 64 EG1...

Страница 70: ...YORK INTERNATIONAL 70...

Страница 79: ...YORK INTERNATIONAL 79 FORM 150 64 EG1...