5894307-UIM-B-0920

28

Johnson Controls Ducted Systems

Notes:

Airflow expressed in standard cubic feet per minute (SCFM).

Motor voltage at 115 V.

SECTION IX: SAFETY CONTROLS

CONTROL CIRCUIT FUSE

A 3-A fuse is provided on the control circuit board to protect the 24-V

transformer from overload caused by control circuit wiring errors. This is

an ATO 3, automotive type fuse and is located on the control board.

BLOWER DOOR SAFETY SWITCH

This unit is equipped with an electrical interlock switch mounted in the

burner compartment. This switch interrupts all power at the unit when

the panel covering the blower compartment is removed.

Electrical supply to this unit is dependent upon the panel that covers the

blower compartment being in place and correctly positioned.

AUXILIARY LIMIT SWITCH

These controls are mounted on the burner assembly. If the temperature

in the area surrounding burner exceeds its setpoint, the gas valve is de-

energized. The operation of this control indicates a malfunction in the

combustion air blower or heat exchanger or a blocked vent pipe con-

nection. Corrective action is required. These are manual reset controls

that must be reset before operation can continue.

PRESSURE SENSOR

This furnace is supplied with a pressure sensor, which monitors the flow

through the combustion air/vent piping and condensate drain system.

LIMIT CONTROLS

There is a high temperature limit control located on the furnace vesti-

bule panel near the gas valve. This is an automatic reset control that

provides over temperature protection due to reduced airflow. This may

be caused by the following:

• A dirty filter

• Indoor fan motor failure

• Too many supply or return registers closed or blocked off

The control module locks out if the limit trips five consecutive times. If

this occurs, the control resets and attempts ignition again after 1 h.

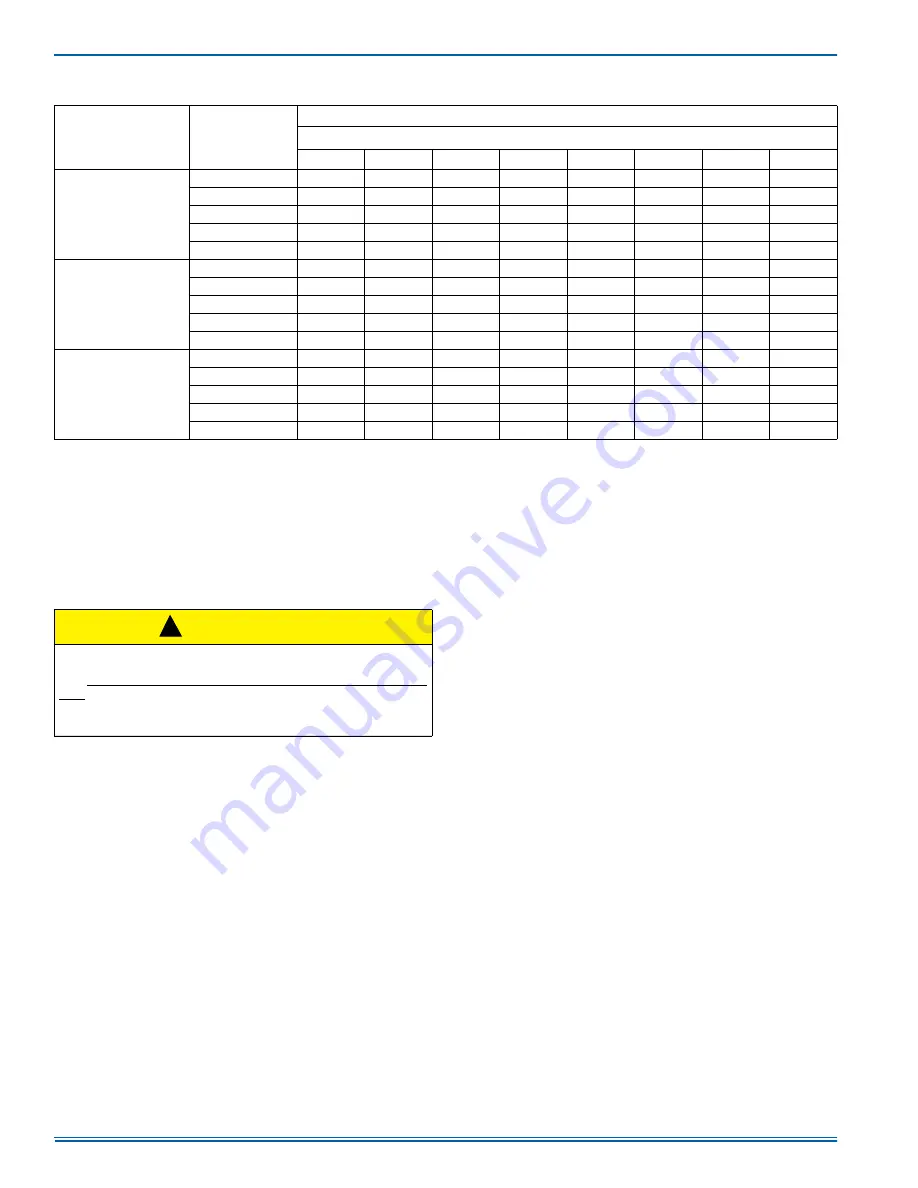

Table 15:

Blower Performance CFM - Any Position (Without Filter)

Models

Speed

Airflow Data

(SCFM)

External Static Pressure (in. H

2

O)

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

TL9E060B12

High

1319

1287

1265

1232

1204

1171

1134

1098

Medium High

1128

1100

1073

1039

997

958

919

871

Medium

952

918

882

846

801

762

717

681

Medium Low

771

734

694

643

601

559

513

461

Low

710

675

632

584

540

491

445

397

TL9E080C16

High

1745

1711

1679

1642

1607

1569

1529

1486

Medium High

1569

1527

1493

1458

1422

1380

1342

1299

Medium

1355

1324

1285

1247

1209

1177

1133

1083

Medium Low

1132

1090

1053

1011

977

923

887

825

Low

968

925

875

832

790

722

650

607

TL9E100C20

High

2171

2123

2092

2038

1995

1944

1893

1853

Medium High

1815

1766

1721

1676

1632

1583

1535

1499

Medium

1596

1555

1501

1453

1412

1384

1335

1288

Medium Low

1377

1316

1276

1223

1170

1131

1076

1029

Low

1256

1204

1149

1102

1058

1008

953

856

CAUTION

Main power to the unit must still be interrupted at the main power dis-

connect switch before any service or repair work is to be done to the

unit. Do not rely upon the interlock switch as a main power discon-

nect.

Blower and burner must never be operated without the blower panel

in place.

!