103904-UIM-B-0505

6

Unitary Products Group

NOTE: All wiring must comply with local and national electrical code

requirements. Read and heed all unit caution labels.

NOTE: It is possible to vary the amount of electric heat turned on during

the defrost cycle of a heat pump. Standard wiring will only bring

on 5 - 10 KW of electric heat during defrost, depending on the

size of the heater.

LINE POWER CONNECTIONS

Power may be brought into the unit through the supply air end of the

unit (top when unit is vertical) or the left side panel. Use the hole appro-

priate to the unit’s orientation in each installation to bring conduit from

the disconnect. The power lead conduit should be terminated at the

electrical control box. Refer to Tables 6, 7, 8 for wire requirements. Also

see Figure 11.

BLOWER SPEED COMFORT SELECTION

NOTE:

1.

Both the "COOL" and the "ADJ" tap must be set for the cooling CFM.

2.

Fan only CFM = 63% of high speed cooling.

3.

Low speed cooling used only with two stage outdoor units. (Speed is preset

to 65% of high speed).

4.

Dehumidification speed is 85% of cooling speed.

5.

When operating in both heat pump and electric heat modes, the CFM will be

whichever is greater.

6.

CFM indicator light flashes once for every 100 CFM. (i.e.: 12 Flashes is

1200 CFM)

These variable speed air handlers are designed to deliver constant

CFM regardless of the external static pressure (ESP) in the ductwork.

Therefore, if too many supply registers are closed, a filter becomes

clogged, or there is a restriction in the ductwork, the motor will automat-

ically operate at a higher speed to compensate for the higher ESP. This

may result in a higher operating sound level.

All CFM’s are shown at 0.5” w.c. external static pressure. These units

have variable speed motors that automatically adjust to provide con-

stant CFM from 0.0” to 0.6” w.c. static pressure. From 0.6” to 1.0” static

pressure, CFM is reduced by 2% per 0.1” increase in static. Operation

on duct systems with greater than 1.0” w.c. external static pressure is

not recommended.

To Set Cooling CFM:

Refer to the outdoor unit technical guide for the recommended airflow

with the matching evaporator coil. Refer to the label in the bag attached

to the blower housing or Table 2 for the possible high speed cooling and

heat pump CFM selections.

Find the recommended system airflow in the Table for the installed Air

Handler model.

Select the "COOL" CFM you need from Table 2. Set "COOL" and "ADJ"

Jumpers on the CFM selection board as indicated in Table 2.

To Set Heat Pump CFM:

The heat pump CFM setting is the same as the cooling CFM. No addi-

tional CFM setting is required, however, you must remove the jumper at

the bottom of the connector board labeled "Remove for Heat Pump" for

heat pump operation (See Figure 8).

To Set Electric Heat CFM:

The blower speed required for the Electric Heat is different than cooling.

Refer to the label in the bag attached to the blower housing or Table 2

for the possible CFM selections. Refer to Tables 5 or 6 for the minimum

required CFM for the electric heater installed. Find the desired airflow in

Table 2. Set the "Heat" Jumper on the CFM selection board to tap

shown.

To Set Delay Profile:

Every variable speed air handler has multiple "blower off delay" profiles

to optimize system performance and efficiency. Refer to Table 2 or the

instructions in the bag attached to the blower housing for the type of

system installed. Set the "DELAY" jumper tap position horizontally on

the CFM selection board for the appropriate setting.

Fan Only CFM:

When the connection is made from "R" to "G", the fan only mode is acti-

vated. In this mode, the blower will deliver 63% of the cooling system

CFM. This connection is factory set from the manufacturer and cannot

be field adjusted.

To Install Humidistat Accessory:

If the system is used with a humidistat accessory, connect the field

wires to screw terminals "R" and "Hum" on the CFM selection board

(See Figures 12, 13, 14, 15, 16, 17, 18, 19, and 20).

IMPORTANT: Remove the jumper at the bottom of the connector board

marked "Remove for Humidistat" for humidistat operation.

TABLE 2: CFM / Comfort Tap Selection

HIGH SPEED COOLING AND HEAT PUMP CFM

MODEL JUMPER

SETTING

N1VSB12 N1VSD12 N1VSC16 N1VSD20

"COOL

TAP"

"ADJ

TAP"

1250 1400

1650 2100 "A" "B"

1230 1230

1570 1980 "B" "B"

1150 1220

1500 1860 "A" "A"

1070 1070

1425 1750 "B" "A"

1035 1100

1350 1675 "A" "C"

1000 1000

1305 1605 "C" "B"

965 965

1285

1575 "B" "C"

820 820

1220

1510 "D" "B"

870 870

1185

1420 "C" "A"

715 715

1110

1335 "D" "A"

785 785

1065

1280 "C" "C"

645 645

1000

1200 "D" "C"

COMFORT SETTING

"DELAY" TAP

UNIT TYPE

Jumper at "A"

Normal Profile

Jumper at "B"

Humid Profile

Jumper at "C"

Dry Profile

Jumper at "D"

Temperate Profile

ELECTRIC HEAT CFM

MODEL

TAP

SELECTIONS

N1VSB12

N1VSD12

N1VSC16

N1VSD20

"HEAT"

1150 1220

1500

1860 "A"

1070 1070

1425

1750 "B"

870 870

1185

1420 "C"

715 715

1110

1335 "D"

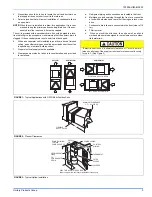

FIGURE 8: CFM Selection Board Detail

DO NOT change the "ADJ" tap position on the CFM selection board

as this will change your cooling CFM previously selected.

CFM SELECTION BOARD

TAP SELECTION

D

C

B

A

D

C

B

A

COOL

HEAT

ADJ

DELAY

REMOVE FOR

HEAT PUMP

HUMIDISTAT