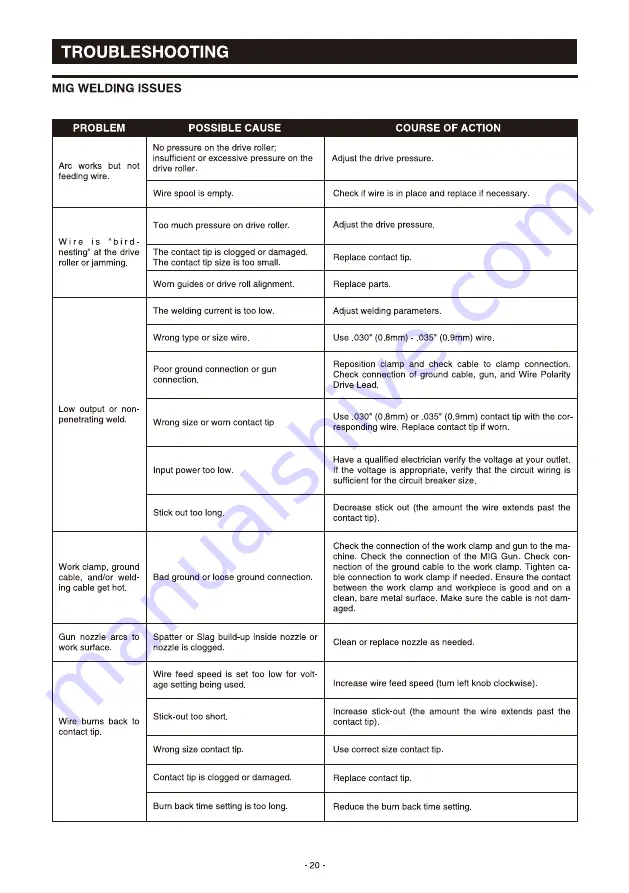

TROUBLESHOOTING

MIG

WELDING

ISSUES

PROBLEM

Arc

works

but

not

feeding wire

Wire

is

"bird

nesting" at the drive

roller or jamming

Low Output or non

penetrating weld.

Work clamp, ground

cable,

and/or weld-

ing cable get hot.

Gun

nozzle

arcs

to

work

surface

Wire

burns

back

to

contact tip.

POSSIBLE

CAUSE

No pressure on the drive roller;

insufficient or excessive pressure on the

drive

roller.

Wire spool is empty

Too much pressure on drive roller.

The contact tip is clogged or damaged

The contact tip size is too small.

Worn guides or drive roll alignment.

The welding current is too low.

Wrong type or size wire

Poor ground connection or gun

connection.

Wrong size or worn contact tip

Input power too low.

Stick out too long

Bad ground or loose ground connection.

Spatter or Slag build-up inside nozzle or

nozzle is clogged

Wire feed speed is set too low for volt-

age setting being used

Stick-out

too

short

Wrong size contact tip

Contact tip is clogged or damaged

Burn back time setting is too long

• 20

COURSE

OF

ACTION

Adjust the drive pressure.

Check if wire is in place and replace if necessary

Adjust the drive pressure

Replace contact tip

Replace parts

Adjust welding parameters

Use 030" (0 8mm) - 035" (0 9mm) wire

Reposition

clamp and check cable to clamp

connection

Check connection

of ground cable, gun, and Wire Polarity

Drive

Lead

Use .030" (0.8mm) or .035" (0.9mm) contact tip with the cor-

responding wire

Replace contact tip if worn.

Have a qualified electrician verify the voltage at your outlet

If the voltage is appropriate, verify that the circuit wiring is

sufficient

for the circuit

breaker

size

Decrease stick Out (the amount the wire extends past the

contact tip)

Check the connection of the work clamp and gun to the ma

chine.

Check

the connection

Of the

MIG

Gun.

Check

con

nection of the ground cable to the work clamp. Tighten ca

ble connection to work clamp if needed. Ensure the contact

between the work clamp and workpiece

is good and on a

clean,

bare metal

surface.

Make

sure the cable

is not dam

aged

Clean or replace nozzle as needed.

Increase wire feed speed (turn left knob clockwise)

Increase stick-out

(the amount the wire extends

past the

contact tip)

Use correct size contact tip

Replace contact tip

Reduce the burn back time setting.