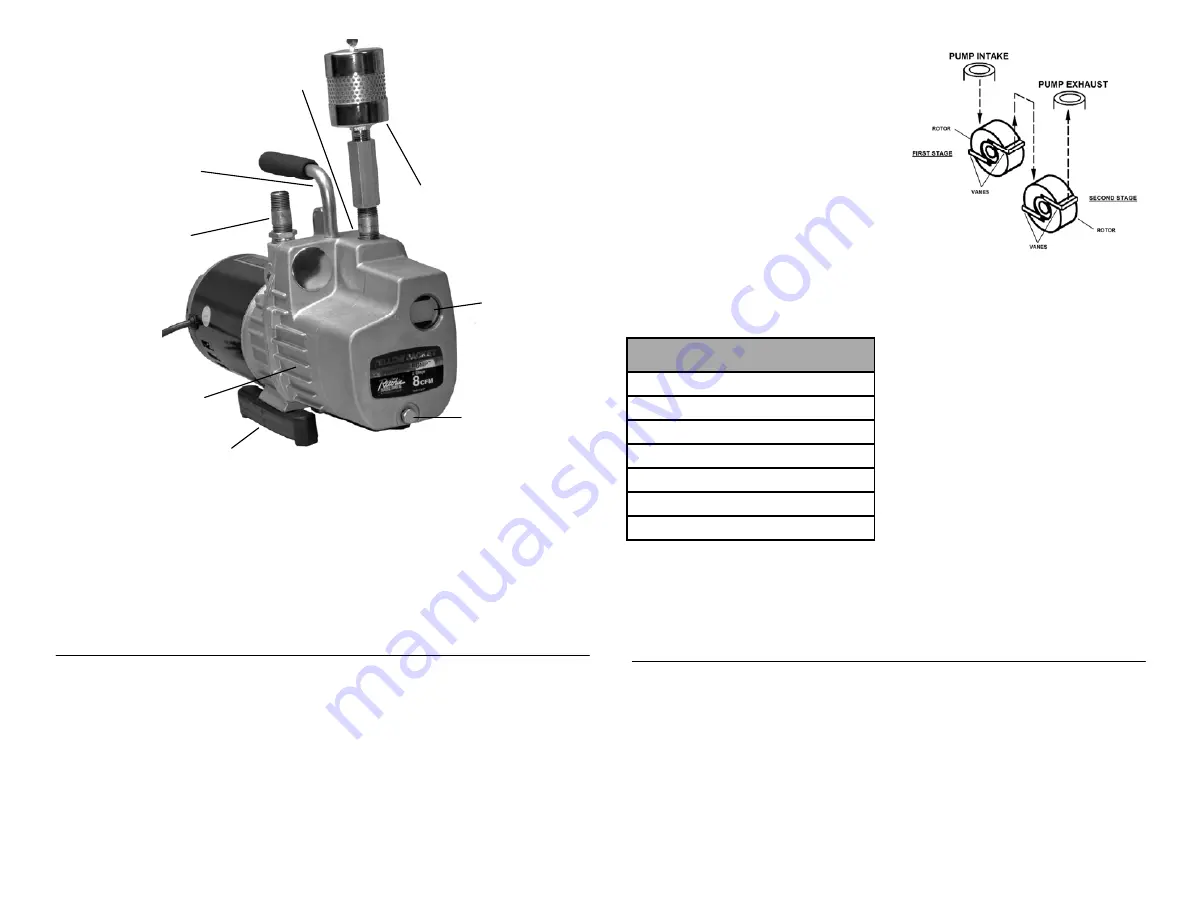

1. Male pipe pump intake. Large hose suggested

for maximum pull down.

2. Gas ballast valve helps remove moisture and

other condensable vapors that have been drawn

into the pump as a result of evacuation. Opening

the ballast allows fresh air to enter the pumping

chamber and keep vapors from combining with

the oil. Vapors escape harmlessly through the

exhaust valve. If combined with oil, vapors can

turn the oil milky white and lower pump per-

formance below specifications.

To operate ballast, turn the valve counter-

clockwise one full turn after evacuation starts.

As the vacuum reading reaches 1000-2000

microns, close the ballast to achieve a deeper

vacuum.

3

1) Male pipe

pump intake

(see below)

Heavy duty high

torque motor for

cold weather

starting.

Longer heat dissipation fins for

a cooler running unit.

Lower operating temperature to

improve efficiency and vacuum.

High resiliency foot pads for

added stability and skid resistance.

Heavy duty metal handle.

Permanently attached to pump

body. Built-in hook hole.

Pump exhaust also doubles as oil fill

port. Use YELLOW JACKET

oil for assurance of a

clean,fast job.

Wide-view

sight glass

for easier

Monitoring

of oil level.

Oil drain valve

for quick draining

and convenient access.

2) Gas ballast valve

(see below)

WARRANTY INFORMATION

Ritchie Engineering guarantees YELLOW

JACKET products to be free of defective material

and workmanship which could affect the life of

the product when used for the purpose for which

it was designed. This warranty does not cover

items that have been altered, abused or returned

solely in need of field service maintenance.

If found defective, we will either replace or repair

at our option products within two years of factory

shipment. Warranty does not cover items that

have been altered, abused (including failure to

use the correct type of vacuum pump oil) or

returned solely in need of field service mainte-

nance.

Returns must be pre-paid.

Warranty does not cover use on lithium bromide

systems.

Features of your New Pump

The 7 Important Steps of Initial Start-Up

The Purpose of the SuperEvac Design

The SuperEvac Pump is a 2-stage rotary vane design

(at right) that increases efficiency and speeds pump

down to 15 microns.

The pump lowers the internal pressure of a refrigera-

tion system until moisture boils into a vapor. As the

moisture is vaporized, it is evacuated by the pump,

helping dehydrate the system. Most technicians try

to achieve between 250 and 1000 microns.

A manometer or electronic vacuum gauge are the

only ways to monitor evacuation progress. Manome-

ter readings are approximate in inches of mercury.

Only an electronic vacuum gauge is accurate enough

to show when you reach the desired micron range.

As the chart shows, only an electronic gauge reads

fine differences to provide assurance that the vac-

uum is low enough to boil the greatest possible

amount of moisture.

How one small drop dampens your profits.

A small drop of moisture can hurt your profits and

reputation.

During new system set-up, protective caps are re-

moved admitting moisture and air into system com-

ponents.

If air – a non-condensable – remains in the system,

it collects on the high side reducing system effi-

ciency. This causes a rise in head pressure. The

discharge valve gets hotter than normal and organic

solids form causing compressor failure.

Moisture in the system can form ice which closes

off openings in expansion valves and cap tubes, and

prevent adequate cooling.

Ultimately moisture and air can produce acids and

sludge which could cause in-warranty failures.

During service and parts replacement, the same

contaminants get in again, and you could be called

back for repairs by a dissatisfied customer.

Moisture and air can even enter through system

leaks. And as the moisture in the air increases, so

does the amount of contamination. The higher the

humidity, the bigger your problem.

A vacuum pump "pulls" air and moisture out of the

system before the system is damaged. The higher

and more complete the vacuum, the more moisture

is removed. That's why your SuperEvac pump is

specifically engineered for high vacuums of 50

microns and better.

Boiling temp

of water

Inches

mercury

Microns

212°F (100°C)

0

760,000

151°F (66°C)

22.05

200,000

101°F (38°C)

27.95

50,000

78°F (26°C)

28.95

25,000

35°F (2°C)

29.72

5,000

1°F (17°C)

29.882

1,000

- 50°F (-46°C)

29.919

50

First stage exhausts into the intake of the second stage

similar to two single stage pumps connected together.

1) Make sure motor is off and name plate volt-

age on motor bottom matches outlet voltage.

2) Remove exhaust filter. Fill with YELLOW

JACKET SuperEvac Pump Oil until oil level

is even with oil level line. Replace exhaust

filter.

3) With the intake port open, switch on the

motor. When pump reaches running speed,

connect the pump to the system.

4) To check the pump's performance, attach a

micron gauge to the intake port, making sure

that the gas ballast valve is closed. Turn on

the pump. The micron gauge will display the

ultimate vacuum reached.

5) Improve cold weather starting by opening

intake and running your pump for 10-15

seconds.

6) Before turning pump off, break vacuum to

atmosphere.

4