10 Maintenance and Inspection

10.2Maintenance for Manipulator

10-11

180788-1CD

HW1484370

MPX2600

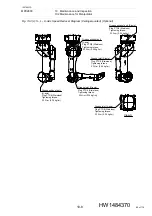

7. For the axis where grease is exchanged, perform a playback operation

indicated in

Table 10-7 “Running- In Operation for Each Axis”

for

running-in the speed reducer with grease.

At this time, grease may be discharged during the operation.

Remove the grease zerk from the grease inlet, and clean and

degrease the tap part and the thread part of the plug. Wrap the seal

tape TB4501 around the plug. Tighten the plug on the grease inlet

with the designated tightening torque. Also, discharge the excess

grease in order not to increase the inner pressure of the speed

reducer. Attach a bag to receive grease such as indicated in

“Grease Receiving Bag (Rough Standard)”

, and then perform the

running-in operation.

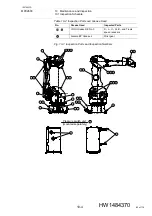

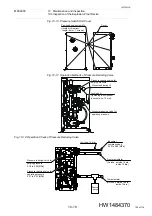

Fig. 10-4: Grease Receiving Bag (Rough Standard)

8. Wipe the discharged grease with a cloth, and reinstall the plug. Clean

and degrease the tap part and the thread part of the plug. Wrap the

seal tape TB4501 around the plug, attach it to the grease inlet, and

then tighten the plug with the designated tightening toque.

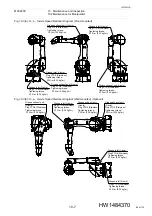

Table 10-7: Running- In Operation for Each Axis

Axis to exchange grease

Running-in operation

Operation

angle

Operation speed

Timer after each

operation

Operating time

S,L,U-axes

±45°

MOVJ VJ=50.00

1.0 s

15 minutes

Tube (inside dia.: 6 mm or more)

Grease receiving bag

Bond for fixing a grease receiving bag

Union (inside dia.: 6 mm or more)

PT3/8

Cut one corner to remove air.

To prevent grease from scattering from the cut corner,

cover the receiving bag with a plastic bag etc. without

being sealed.

92 of 116