4

Pump

Piping

Valve

Material

Hose

Air hose Air regulator

3.4 Installing the Pressure Feed Material Hose

For pressure-feeding oil by piping at a long distance, observe the following procedure.

- Do not connect the pump directly to the piping. Otherwise, when the pump is

operated, the piping is damaged, the pump generates large noise, the pump does

not permit changing the drum can, and the pump cannot be serviced. Be sure to

connect a flexible hose between the pump and the piping.

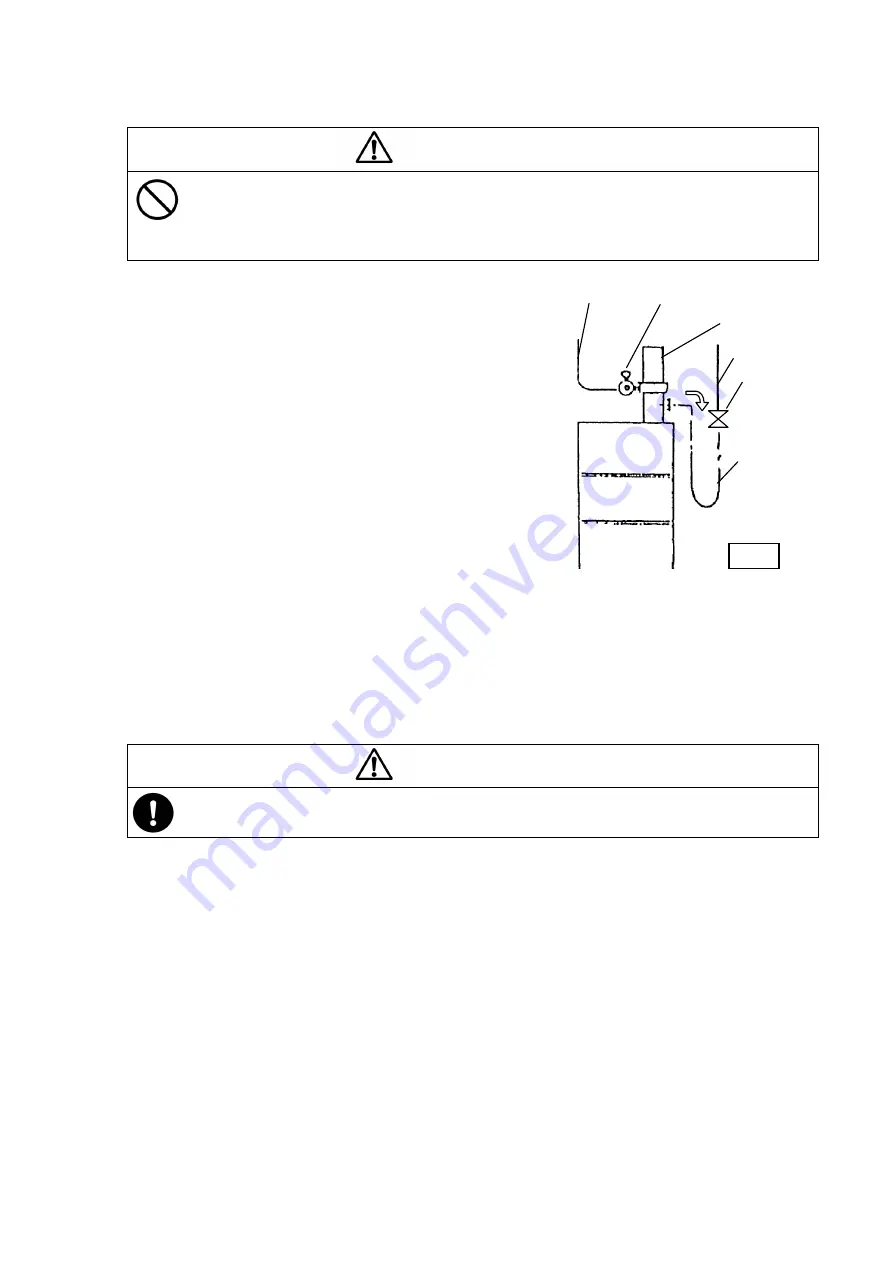

1) Install the hose union and material hose

(separately available) to the material discharge

port (Rc 3/4) of the pump. Tighten the hose

union with a spanner so as not to make

thematerial hose loose. In this case, wind the

seal tape that is available on the market around

the male screw of the hose and then screw it.

2) Install a valve between the end of the hose and

the piping. (Fig. 4)

3) Be sure to install a relief valve so that leak may

not be caused to the piping or damage may not

be given to the hose connecting portion by the

liquid pressure increased by temperature

changes in the piping. The relief valve should

be installed near the pump.

3.5 Air Connection

1)

Install the air regulator (separately available) at the air supply port of the pump. The

dedicated air regulator is available as the standard product. Please use it.

2) Connect the air hose from the compressor to the IN side of the air regulator.

- Be sure install the air regulator at the air supply port for the safe use of the pump.

(The air regulator consists of a reducing valve and a pressure gauge.)

[NOTE]

●

When air is supplied to the air hose, the pump is in operation.

Before connecting the air hose, be sure to turn the knob of the air regulator

counterclockwise to reset the pointer of the pressure gauge to “0”.

●

Using the air regulator permits adjusting the supply air pressure to the pump and

reducing the wasteful motion of the pump, with the result that the operability is improved

and the pump life is extended.

Regarding the method of adjusting the air pressure with the air regulator, the pressure is

increased by turning the knob clockwise (the pointer of the pressure gauge gradually raises

from “0”) and reduced by turning it counterclockwise (the pointer of the pressure gauge

goes back to “0”).

In the normal operating status, the pointer of the pressure gauge should be at 0.3 to 0.5

MPa.

CAUTION

CAUTION

Fig.4

Содержание SH-160A10

Страница 17: ...12 5 5 Parts Disassembly Drawing and Parts List Parts Disassembly Drawing...

Страница 21: ...MEMO...