15

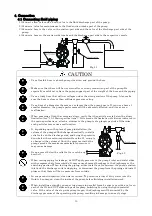

5. Operation

5.1 Method of operation

CAUTION

• Before starting the pump, make sure that all piping is properly connected.

• Also, before starting the pump, make sure that all the bolts are securely tightened.

(Refer to the maintenance manual for the bolts that a regulation torque are explained.)

• Make sure that the air valve, regulator and the drain valve on the discharge side are closed.

Also, make sure that the valve on the suction side is opened.

1) Start the air compressor.

2) Open the air valve in front of each piece of peripheral equipment, and adjust the supply air pressure

with a regulator to within the permissible range (see “10.1 Main specifications after” P.20).

3) Open the flow valve on the discharge side.

4) Press the RESET button, and then slowly open the air valve of the pump.

5) First, verify that fluid is flowing inside the piping and is being pumped to the discharge side, and then

fully open the air valve.

6) Again adjust the supply air pressure with a regulator to within the permissible range (see [10.1 Main

specifications]).

CAUTION

• Do NOT open the air valve suddenly.

• In case of use lubricator, must be used turbine oil none addition class 1 turbine oil

(equivalent ISO VG32 grade) for lubricants. Do not apply lubricants more than required and

also do not use any other lubricants, which designated on this instruction manual. This may

cause of pump problem and there is danger of serious bodily damage.

5.2 Flow adjustment

• Adjust the flow valve on the discharge side. For the relationship among the flow, supply air pressure

and discharge pressure, see “10.3 Performance curve”.

CAUTION

• As you start closing the flow valve, the supply air pressure may rise. Make sure that the

pressure is kept within the normal operating range (see “10.1 Main specifications”).

• Depending upon the viscosity and specific gravity of the fluid, the suction stroke and other

conditions, the permissible suction flow speed of fluid into the pump will vary; however, if

the pump speed (flow speed of fluid) increases greatly, cavitation will occur, and this not only

will reduce pump performance, but it may cause a malfunction. Adjust the supply air

pressure as well as the flow in order to prevent cavitation.

• If fluid is not discharged after you start the pump, or if you hear an abnormal noise or notice

any irregularity, shut down the pump immediately (see “8. Troubleshooting”).