14

4.2 Connecting air piping

WARNING

•

Before starting work, make sure that the air compressor is shut off.

1) Connect an air valve, air filter, regulator and if necessary lubricator (hereinafter called the "peripheral

equipment") to hose which connected to compressor.

Install air valve on the air inlet of the pump. See <NOTE> for the details.

2) Install these peripheral items supported by brackets, etc., near the pump.

3) Connect the hose from the peripheral equipment to the air valve of the pump's supply port.

CAUTION

• Use a flexible hose to absorb pump vibration, and ground the hose.

• Make sure that there will be no external force on any connection part of the pump. Be

especially careful not to have the pump support part of the weight of the hose and the piping.

• The piping and the peripheral equipment may become clogged with sludge. Clean the inside

of the piping for 10 to 20 seconds before connecting it to the pump.

• Be sure to sufficiently ground the piping and peripheral equipment.

• For the DP-10 series, lubrication is required.

<NOTE>

•Air piping size should be equal to the inlet port of the pump to supply enough air to run the pump. The air

compressor should be able to provide adequate air flow to the pump. Attach the compressor as close as

possible to the pump, considering operability and stability of air pressure.

•If you use a solenoid valve as the air valve, be sure it is a three-way valve. When the valve is closed, the

internal compressed air of the pump will be released, and this will switch the spool to its normal position.

•Use of a coupler for the connection part of each hose will make operation and maintenance easier.

•If you use the pump intermittently the pump will not require lubrication. However lubrication is

recommended if running the pump continuously for long periods or using very dry air or at high

temperatures. This will guarantee the life of the pumps seals.

*High temperature operation: When transferring liquid whose temperature exceeds 70°C

*Continuous operation: When the pump operates continuously for longer than 1 hour and is stopped for

less than 15 minutes.

*Lubrication: Use only turbine oil Class 1 grade oil (equivalent to ISO VG 32), under the following

conditions; Oil concentration at 50mg/m³, Absolute pressure at 0.1MPa. Maximum temperature of 20°C

and Humidity at 65%.

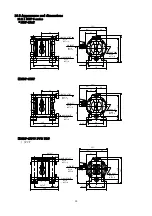

Fig.4.3