Apr. 2017

P 12

da Vinci

Jr.1.0A

CLEAN NOZZLE

CHANGE NOZZLE

Guide to Clean Nozzle

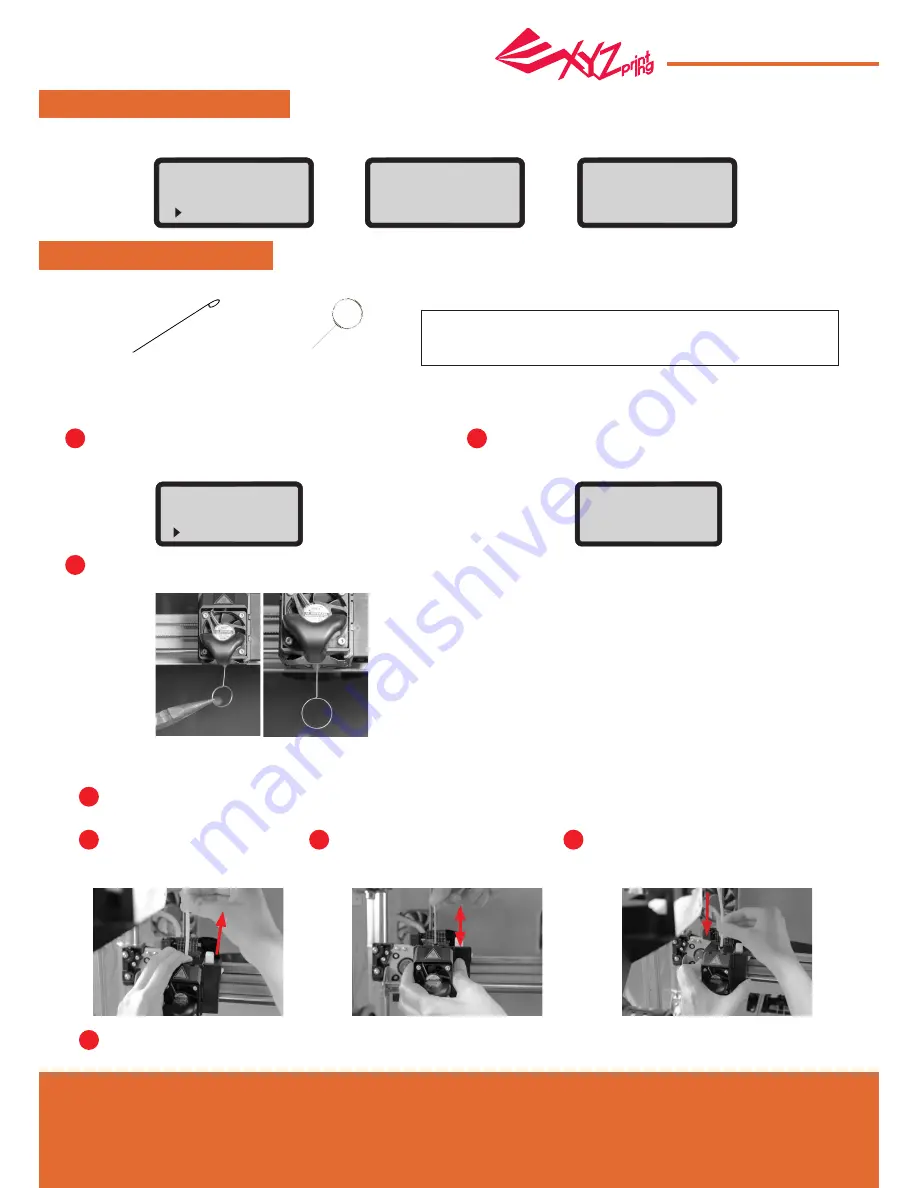

Tools Preparation

Select "UTILITIES" > "CLEAN NOZZLE" > "YES".

Insert the cleaner wire into the hole of the nozzle carefully with a nipper.

After inserting the wire, press "OK" to exit.

Wait for the printer to warm up to the operating temperature.

You can start cleaning when "TIME TO CLEAN YOUR

NOZZLE" is displayed.

Note: If the materials still cannot extrude normally after performing the CLEAN NOZZLE function,

please follow the steps below to clean the feeding path again.

“UNLOAD” function again and wait until the extruder is heat up to 150

◦

C. (Care should be taken during the operation to

avoid potential burn injuries.)

Press the spring around the

feeding path and pull out the guide

tube. (Do not detach the black bus

above the nozzle.)

Insert the feeding path cleaning pin into

the feeding path as far as it can go, and

stick it back and forth to remove the

carbon deposits and dirt completely.

After cleaning, insert the guide tube onto the

nozzle.

Please place the extruder to original position (HOME AXIS) and calibrate the print bed (CALIBRATE). Then, do print bed leveling

after completing clean nozzle. (Please refer to the "Print Bed Leveling" section).

START CLEANING

NOZZLE NOW?

NO

YES

TIME TO CLEAN

YOUR NOZZLE?

[ OK ] WHEN FINISH

Carbon deposits and dirt accumulated in the nozzle will increase

with the printing times and impact the printing quality. We suggest

that you clean the nozzle after every 25 hours of printing.

A. Feeding Path Cleaning Pin

B. Cleaner Wire

Carry out the CHANGE NOZZLE function before changing modules. Once the printing module has moved to the operating

position, you can

turn off the power

and change the module.

YOU CAN TURN OFF

POWER & CHANGE

NOZZLE NOW

CHANGE NOZZLE

MODULE NOW ?

NO

YES

REPOSITION NOW

PLEASE WAIT

1

1

2

3

4

5

3

2

●

●

UTILITIES