WQG-10029-01

Calibrating D/A Converter

The D/A converter is factory set to the specified

frequency (noted on the label affixed to main

circuit board) and field recalibration is usually not

required. If it becomes necessary to recalibrate the

D/A converter, the following procedure must be

followed and high quality test equipment used. Any

component changes must be made with equivalent

components.

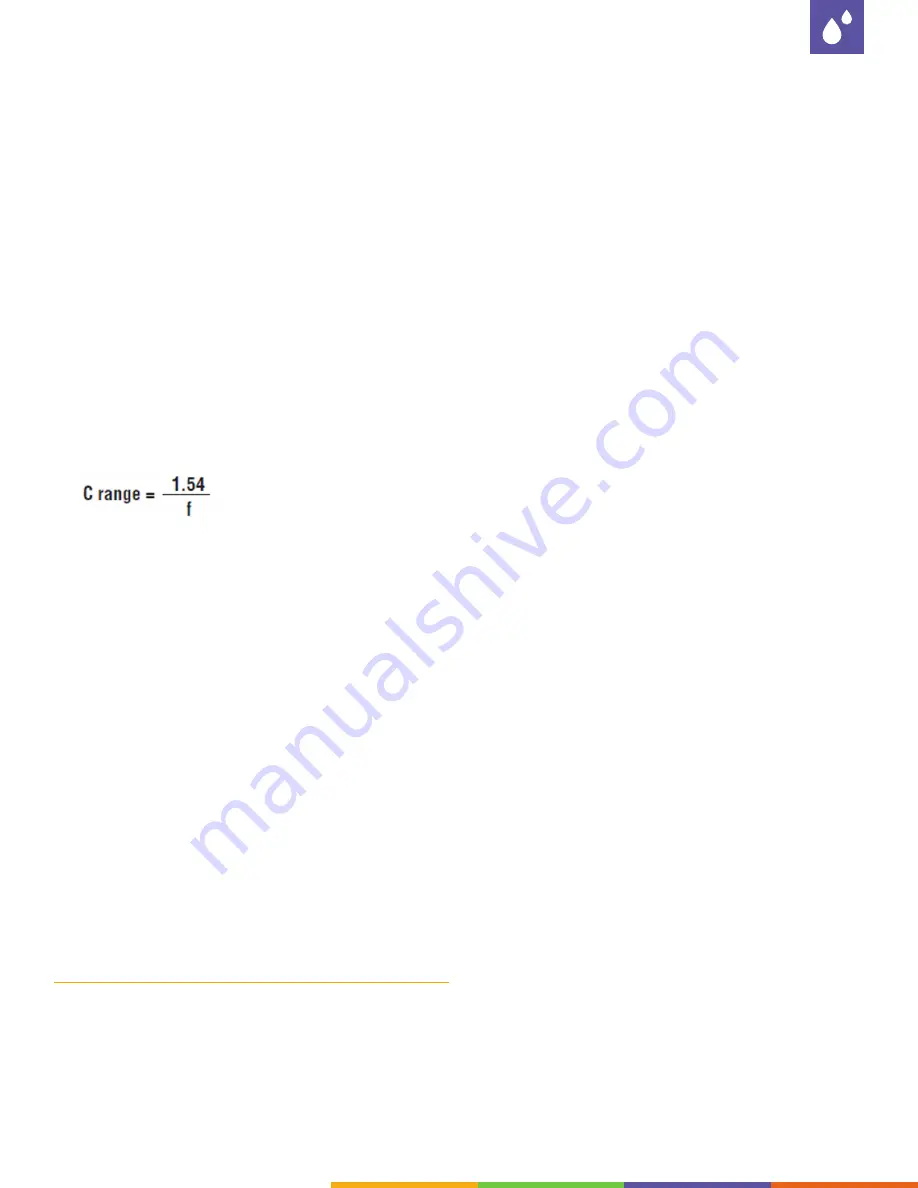

Calculating the RANGE capacitor’s value

To change the input frequency, the range capacitor

may have to be replaced.

Use the formula to determine the necessary value.

For example, to obtain full scale DC output of 20

ma DC at a full scale input pulse rate of 10 pulses/

second, a capacitor of .15 MF is needed. The

stability of the range capacitor affects the stability

of the converter; only polycarbonate or polystyrene

capacitors should be used. The zero and range

potentiometers provide a minimum adjustment

range of + or -10% to accommodate capacitor

tolerances (for the main output).

Test Equipment Setup

Connect signal source onto Act-Pak terminals

#16 and #14, positive and ground respectively.

Signal sources may be solid state or switch driven.

Regardless of the device being used, it must

develop a square wave capable of sinking 50 mA

and interrupting 50 volts. To determine the precise

input frequency, it is suggested that a digital counter

also be connected to terminals #16 and #14.

t

WARNING!

ELECTRICAL HAZARD. Use caution when working with

disassembled AC electrical components.

Act-Pak® Electronic Instrumentation

Models 1100D and 1100DN Quick Guide

Calibration: Proportional Output (4-20 mA) with a

Voltmeter

1. Connect a load resistor across terminals #5 (+) and

#6 (-).

2. This resistor may be of any value less than or equal

to 500 ohms.

3. Connect a digital voltmeter across terminals #5 (+)

and #6 (-)

4. Apply power to the instrument with the signal

source off. The analog output signal should be 4

mA indicated by a 2.0 volt reading if a 500 ohm

load resistor is used.

5. Adjust the ZERO potentiometer, if necessary.

6. Turn on signal source and adjust to full scale input

frequency.

7. Adjust the SPAN potentiometer to obtain a 10.0

volt reading on the voltmeter.

8. If SPAN adjustment is required, repeat step

“c” to check the zero setting; adjust and reset,

if necessary. Each time the ZERO or SPAN

potentiometers are moved, the opposite setting

must be checked until no adjustment is required.

Calibration: Proportional Output (4-20 mA) with a

Milliampere Meter

1. Remove all connections on terminals #5 (+) and #6

(–).

2. Connect a milliampere meter across terminals #5

(+) | and #6 (–).

3. Apply power to the instrument with the signal

source off. The analog output should be 4.0 mA.

4. Adjust the ZERO potentiometer if necessary.

5. Turn on the signal source and adjust to full scale

input frequency.

6. Adjust the SPAN potentiometer to obtain a 20 mA

reading.

7. If SPAN adjustment is required, repeat step

“c” to check the zero setting; adjust and reset,

if necessary. Each time the ZERO or SPAN

potentiometers are moved, the opposite setting

must be checked until no adjustment is required.