FieldLogic errors

This section describes some of the most common errors that you may encounter while

using FieldLogic Tools and suggests possible corrective actions.

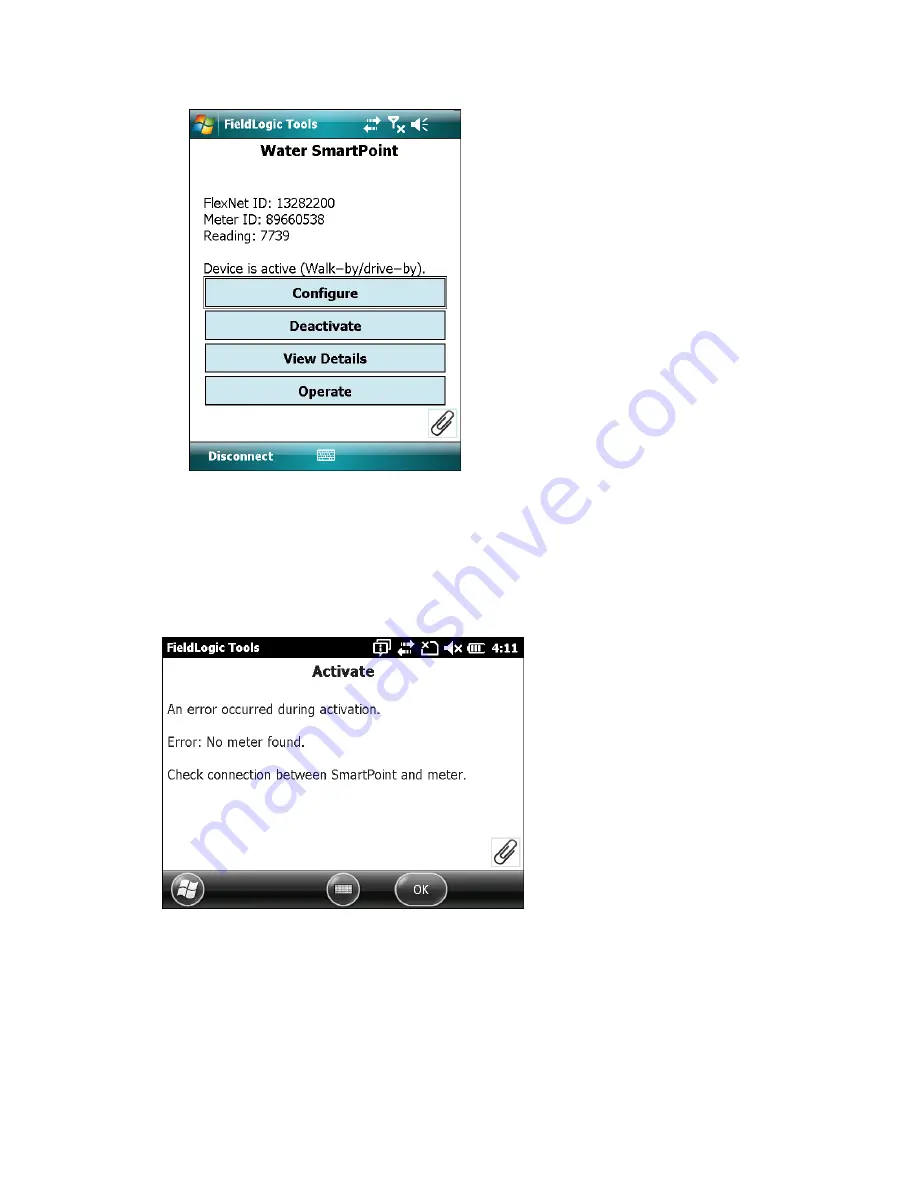

Activation errors

If SmartPoint module activation fails, FieldLogic Tools may display an error message.

The following table lists common activation errors along with possible causes and

corrective actions.

6 Two-way SmartPoint modules | 28