8

STEP 7 - Testing and Inspection

V

CLOSING

LEVEL

INSTALLATION COMPLETE

C.

Line

Load

N.

N.C.

O.

C.

Load

or

Burner

Circuit

Low

Water

Alarm

N.

N.C.

Neutral

120 V.A.C.

or 24 V.A.C.

Supply

HOT

O.

b.

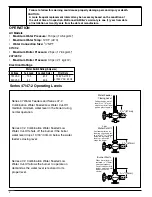

Based on the mode of operation required for

your application, complete the appropriate

corresponding step.

When the water feeder is used as a low water

cut-off switch and/or a low water alarm, connect

the "Hot" wire to the "Common" contact. Using a

flat head screw driver, tighten the screw. Connect

the low water alarm to the “Normally Open” contact

and tighten the screw. Connect the burner or load

circuit wire to the “Normally Closed” contact and

tighten the screw.

OR

When the water feeder is used as a pilot switch

to a holding coil of a motor starter or relay,

connect as shown in the diagram to the right.

Low water cut-off switch and/or low water alarm

Pilot switch for motor starter or relay

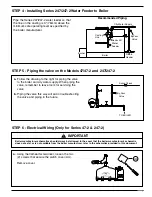

The feeder should be blown down after initial installation

before leaving site. It should also be blown down as

recommended in the Maintenance section of these

instructions.

• Burner should be on and water level above 'closing

level' of feeder.

•

Slowly

open the water feeder blow down valve 'V'

which will lower the water level in the float chamber.

As water flows out the blow down pipe, you should

begin to hear the feeder valve open.

• If the feeder has a #2 switch, the burner should stop.

• Close the water feeder blow down valve 'V'. The water

level should return to a safe operating level and the

burner should turn on.

To prevent serious personal injury from steam pipe

blow down, connect a drain pipe to the control

opening to avoid exposure to steam discharge.

Failure to follow this caution could cause personal

injury.

!

CAUTION

Blow Down of Feeder