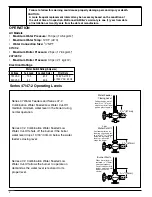

E

F

D

10-5/8"

(270mm)

G

d.

Determine the position of the black "Y" casting (F).

If gauge glass tappings (D) and (E) are less

than 10

5

⁄

8

" (270 mm) apart, install the black

"Y" casting (F) as depicted in the diagram to the

top right.

OR

If gauge glass tappings (D) and (E) are

greater than 10

5

⁄

8

" (270 mm) apart, invert

the black "Y" casting (F) as depicted in the

diagram to the bottom right.

OR

If gauge glass tappings (D) and (E) are

greater than 14" (356 mm) apart, invert the

black "Y" casting (F) as depicted in the diagram

to the bottom right and install a longer nipple (G).

F

INVERTED “Y” CASTING

Note:

Reverse union

nuts, packing

and plug.

Tighten top

nut securely.

G

4

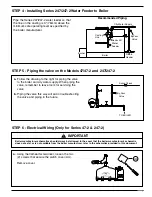

STEP 2 - Preparation (Installing Quick Hook-up Fittings to Water Feeder)

a.

Turn the boiler off.

A

b.

Drain the water in the boiler until the level falls below the lower

gauge glass connection (A). Allow the boiler to cool to 80˚F

(27 ˚C) and allow the pressure to release to 0 psi (0 bar).

B

C

c.

Remove the water glass (B) and gauge glass connections (C)

from the boiler.

OFF

ON