June 2014

3-3

Xerox® WorkCentre® 3025 Multifunction Printer Service Manual

Image Quality Overview

Image Quality

Image Quality Overview

Image quality defects can be attributed to printer components, consumables, media, internal

software, external software applications, and environmental conditions. To successfully trou-

bleshoot print-quality problems, eliminate as many variables as possible.

If the print-quality defect is still present after printing on approved media from an unopened

ream of paper, investigate software applications and environmental conditions. Check the tem-

perature and humidity under which the printer is operating. Compare this to the Environmental

Specifications listed in Section 6.

When analyzing a imaging defect, determine if the defect is repeating or random. Check the

Supplies Information Report for end of life conditions. Inspect the visible surfaces of all rollers

for obvious defects. If a cursory inspection does not reveal any obvious defects, continue trou-

bleshooting the defect.

WARNING

Do not perform repair activities with the power on or electrical power supplied to the

machine. Some machine components contain dangerous electrical voltages that can

result in electrical shock and possible serious injury.

DANGER: Ne pas effectuer de dépannnage avec le contact principal activé ou avec l'ali-

mentation électrique appliquée à la machine. Certains éléments de la machine compor-

tent des tensions électriques dangereuses qui peuvent causer un choc électrique et de

graves blessures.

AVVERTENZA: Non effettuare alcuna riparazione con l'alimentazione elettrica inserita.

Alcuni componenti contengono corrente ad alta tensione che può provocare forti

scosse e gravi ferite.

VORSICHT: Es dürfen erst Reparaturarbeiten durchgeführt werden, wenn das Gerät aus-

geschaltet ist oder der Netzstecker nicht mehr mit der Stromquelle verbunden ist. Ein-

ige Komponenten des Gerätes sind stromführend und können daher zu ernsthaften

Verletzungen oder Stromschlägen führen.

AVISO: No realice reparaciones con la máquina encendida o conectada a la corriente.

Algunos componentes de la máquina contienen voltajes eléctricos peligrosos que

pueden producir una descarga eléctrica y causar daños graves.

Defects Associated with Specific Components

To aid with diagnosis, the list below outlines image defects associated with specific compo-

nents.

Laser Scanner Unit:

•

Black Print

•

Vertical white lines

•

Curved lines

Transfer Roller:

•

Uneven Density

•

Background contamination

•

Ghosting

•

Vertical white lines

•

Vertical black line or band

•

Stains on the page back

Fuser:

•

Ghosting

•

Stains on the page back or front

•

Poor image adhesion

Print Cartridge:

•

Uneven density

•

Background contamination

•

Spots, smudges, or smears

•

Ghosting

•

Vertical white lines

•

Vertical black line or band

•

Stains on the page front

•

Blank prints

•

Black prints

•

Horizontal Black lines or bands

After determining the defect type and possible source, match the defect with those listed in

Table 1

. Go to the RAP listed to correct the defect.

Image Defect Definitions

Table 1

lists image defect definitions and the RAP used to correct the problem.

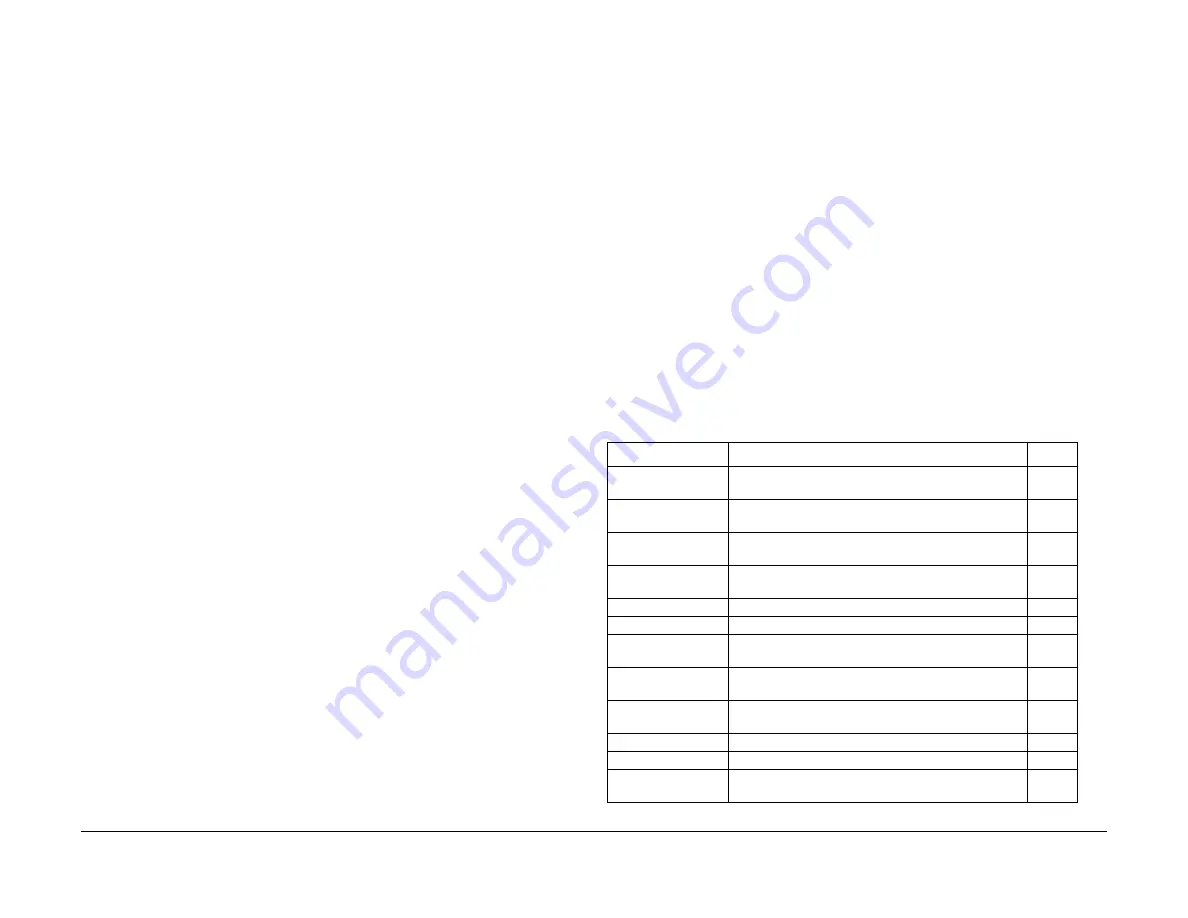

Table 1 Image Defect Definitions

Defect

Definition

Go To

Vertical Black Line

and Band

Vertical black lines or bands occur in the printed image. IQ1

Vertical White Line

and Band

Vertical white lines or bands occur in the printed image. IQ2

Horizontal Black

Band

Periodic dark or blurry horizontal bands in the printed

image.

IQ3

Spots

Random or periodic dark areas in the low density

areas of a print, or voids in the dark areas of a print.

IQ4

Low Image Density

Printed image is light with no ghosting.

IQ5

Black or Dark Image

Printed image is totally dark or black

IQ6

Uneven Density

Print density is uneven between the left and right por-

tion of the printed image.

IQ7

Background

Uniform toner contamination in most or all non-image

areas.

IQ8

Residual Image

(Ghosting)

The image from a previous print appears on the current

print.

IQ9

Side 2 Staining

Side two of a simplex or duplex print is stained.

IQ10

Blank Page

The entire image area is blank.

IQ11

Partial Image Dele-

tions

Areas of the printed image are light or missing entirely

on limited areas of the paper.

IQ12

Содержание WorkCentre 3025BI

Страница 1: ...Xerox WorkCentre 3025BI NI Service Manual 702P02831 June 2014 Initial Issue ...

Страница 2: ......

Страница 4: ...June 2014 2 Xerox WorkCentre 3025 Multifunction Printer Service Manual Draft ...

Страница 6: ...June 2014 ii Xerox WorkCentre 3025 Multifunction Printer Service Manual Introduction ...

Страница 18: ...June 2014 1 2 Xerox WorkCentre 3025 Multifunction Printer Service Manual Service Call Procedures ...

Страница 24: ...June 2014 2 2 Xerox WorkCentre 3025 Multifunction Printer Service Manual Status Indicator RAPs ...

Страница 40: ...June 2014 2 18 Xerox WorkCentre 3025 Multifunction Printer Service Manual 20 900 Status Indicator RAPs ...

Страница 42: ...June 2014 3 2 Xerox WorkCentre 3025 Multifunction Printer Service Manual Image Quality ...

Страница 52: ...June 2014 3 12 Xerox WorkCentre 3025 Multifunction Printer Service Manual IQ12 Image Quality ...

Страница 54: ...June 2014 4 2 Xerox WorkCentre 3025 Multifunction Printer Service Manual Repairs ...

Страница 94: ...June 2014 4 42 Xerox WorkCentre 3025 Multifunction Printer Service Manual REP 1 25 Repairs ...

Страница 96: ...June 2014 5 2 Xerox WorkCentre 3025 Multifunction Printer Service Manual Parts List ...

Страница 114: ...June 2014 6 2 Xerox WorkCentre 3025 Multifunction Printer Service Manual General Procedures and Information ...

Страница 132: ...June 2014 6 20 Xerox WorkCentre 3025 Multifunction Printer Service Manual GP 9 GP 10 General Procedures and Information ...

Страница 144: ...Xerox WorkCentre 3025 Multifunction Printer Service Manual June 2014 BSDs THIS PAGE INTENTIONALLY BLANK ...