Commissioning

Worcester Commercial Boiler Series – 6720814332 (2019/04)

34

8.4

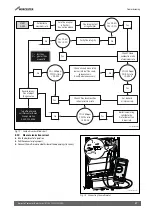

Adjusting the output

The output of the boiler can be adapted to the heat energy demand via

the setup menu. Proceed as follows:

▶ Adjusting the output via the setup menu (

Chapter 7.2).

Observe the following table when making the adjustment.

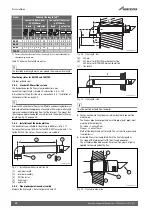

Table 15 Output as a percentage [kW]

8.5

Setting the maximum boiler temperature

▶ Adjust the maximum set flow temperature in the setup menu

(

Chapter 7.2).

8.6

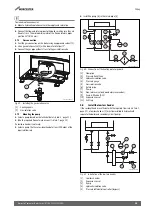

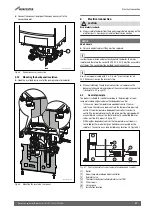

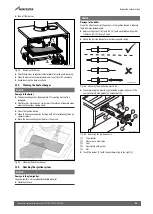

Adjusting the pump group

In order for the heating system to function correctly the pump must be

controlled by the burner control unit. To do so, the pump setting must be

set to the medium level.

▶ Set the pump via the red knob on the front to medium level, “Ext. in”.

▶ Adjust the pump run-on time in the setup menu (

Chapter 7.2).

8.7

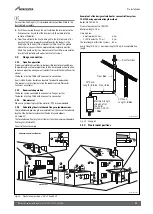

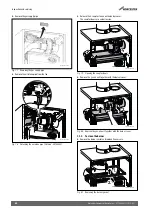

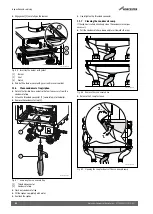

Testing the gas supply pressure

Measure the gas supply pressure when the burner is in operation at full

load. Proceed as follows:

▶ Take the boiler out of operation.

▶ Remove the casing.

▶ Close gas isolation valve.

▶ Make sure the heating system can dissipate the heat generated.

▶ Undo the test nipple for the gas supply pressure [1] by turning it

through 2 revolutions.

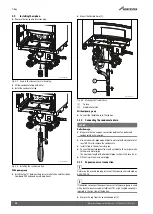

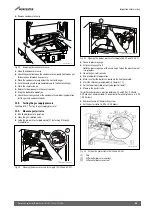

Fig. 65 Open the burner pressure nipple at the 50-V2 and 65-V2

Fig. 66 Open the burner pressure nipple at the 85-V2 and 100-V2

▶ Set the pressure gauge to “0”.

▶ Connect test hose to the plus connector of pressure gauge and the

test nipple for the gas supply pressure [1].

Fig. 67 Connecting the pressure gauge at 50-V2 and 65-V2

Display

Boiler type

[%]

50-V2

65-V2

85-V2

100-V2

20

–

14.3

–

20.8

25

–

17.8

20.8

25.7

30

14.3

21.2

25.0

30.6

35

16.8

24.7

29.3

35.6

40

19.4

28.1

33.5

40.5

45

21.9

31.6

37.8

45.4

50

24.5

35.0

42.0

50.3

55

27.0

38.5

46.3

55.2

60

29.6

41.9

50.5

60.2

65

32.1

45.4

54.8

65.1

70

34.6

48.8

59.0

70.0

75

37.2

52.3

63.3

74.9

80

39.7

55.7

67.5

79.8

85

42.3

59.2

71.8

84.7

90

44.8

62.6

76.0

89.7

95

47.4

66.5

80.3

94.6

– –

49.9

69.5

84.5

99.5

0010010025-001

1

0010010026-001

1

0010010027-001

1