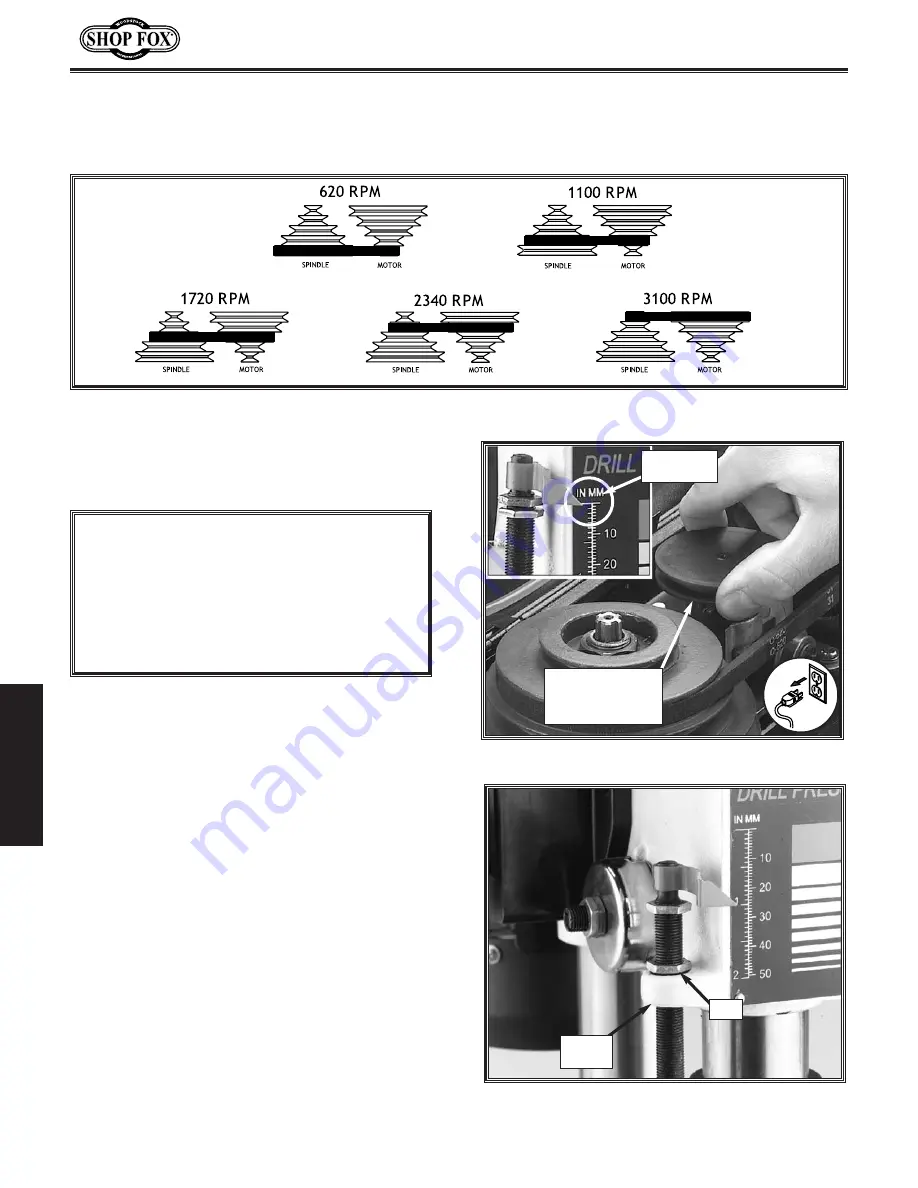

Use

Figure 30

to select the optimum motor-to-spindle pulley ratio for drilling, cutting, and sanding

operations. Refer to the

Drill, Cutter, and Saw RPM Chart

on

Page 19

for suggested tool RPMs.

Figure 30.

Drill Press RPM Chart.

-18-

Your new drill press comes fitted with a depth

stop that allows drilling holes at a preset depth.

To adjust the drilling depth, do these steps:

1.

UNPLUG THE DRILL PRESS!

2.

Rotate the oscillator pulley until the depth

stop pointer indicates “0”. See

Figure 30.

3.

Loosen the jam nut on the depth stop rod.

4.

Move the spindle down while watching the

pointer-to-scale relationship and stop at

the desired depth.

5.

Turn the lower nut while maintaining this

depth until the nut comes into contact

with the stop flange. See

Figure 31.

6.

Allow the spindle to return to its original

position and tighten the jam nut against

the stop nut while making sure the stop

nut does not move.

7.

Drill a test hole into scrap stock before

drilling into any workpiece, and readjust

depth stop if necessary.

Figure 31.

Nut contacting stop flange.

Figure 30.

Retracting the oscillator for drilling.

Stop

Flange

Nut

Rotate Oscillator

Pulley Until

Depth Stop Reads

Zero.

Depth Stop

Reads “0”

NOTICE

BACK-OFF the depth stop completely and

secure the stop nuts before using the oscillat-

ing feature. If the depth stop is left adjusted

for a shallow hole, or the nuts rattle down to

the stop while in operation, the depth stop

will bottom out and break the oscillator.

ADJUSTMENTS

Drilling Depth

Drill Press RPM Chart

Содержание SHOP FOX W1667

Страница 21: ... 19 ADJUSTMENTS ...

Страница 22: ... 20 ADJUSTMENTS ...

Страница 29: ... 27 Parts Diagram MAINTENANCE ...

Страница 35: ......

Страница 36: ......