Operation 9

MCPBH-B (Rev. 4/20/2007)

OPERATION

Safety instructions are important! Read all

attachment and power unit manuals; follow all

safety rules and safety decal information. (Replace-

ment manuals and safety decals are available from

your dealer.) Failure to follow instructions or safety

rules can result in serious injury or death.

Power unit must be equipped with ROPS and

seat belt/operator restraint. Keep seat belt/operator

restraint securely fastened/engaged. Falling off

power unit can result in death from being run over

or crushed. Keep ROPS systems in place at all

times.

Operators must be instructed in and be capable

of the safe operation of the equipment, its attach-

ments, and all controls. Do not allow anyone to

operate this equipment without proper instructions.

NOTICE

■

Backhoes must be equipped with an auxiliary

hydraulic system capable of supplying continuous

flow for hydraulic motor operation.

PRE-OPERATION CHECK LIST

(Owner’s Responsibility)

___ Review and follow all safety rules and safety

decal instructions on page 5 through page 8.

___ Check that all safety decals are installed and in

good condition. Replace if damaged.

___ Check that all shields and guards are properly

installed and in good condition. Replace if

damaged.

___ Check that equipment is properly and securely

attached to power unit.

___ Check that all hardware and cotter pins are

properly installed and secured.

___ Do not allow riders.

___ Keep all bystanders away from equipment

working area.

___ Check all lubrication points and grease as

instructed in Lubrication Points‚ page 16.

___ Check that all hydraulic hoses and fittings are

in good condition and not leaking before start-

ing power unit.

___ Check that hoses are not twisted, bent sharply,

kinked, frayed or pulled tight. Replace any

damaged hoses immediately.

___ Make sure power unit ROPS and seat belt are

in good condition. Keep seat belt securely fas-

tened during operation.

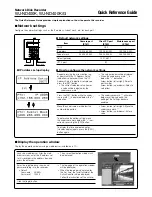

Routing Hydraulic Hoses

NOTE: The planer is shipped without hoses. The

customer must supply and install hoses prior to

operation.

1. Remove the caps from the motor fittings (1, 2, 3) as

shown in Figure 1.

2. Attach the casedrain hose to the fitting on the

motor (1).

3. Attach the return hose to the fitting on the motor

(2).

4. Attach the pressure hose to the fitting on the motor

(3).

NOTICE

■

Casedrain must be routed directly back to the

reservoir. Excess case pressure over 50 psi in

motor will result in motor failure.

Figure 1.

Do not allow bystanders in the area when oper-

ating, attaching, removing, assembling, or servic-

ing equipment.

WARNING

DP2

A

WARNING