COMMODORE 1

1.

Remove belt guard.

2.

Roll belt off motor pulley.

3.

Loosen set screws in locking collars

on pivot shaft. Slide out shaft to

lower brush head assembly.

BRUSH DRIVE MOTOR

1.

To

access motor mounting bolts,

lower brush head assembly.

2.

Disconnect motor leads from terminal

block.

3.

(4)

motor mounting screws.

4.

Lift out motor and repair or replace

as required.

NOTE: When reinstalling motor,

make sure pulleys are properly

aligned and belt tension is adjusted

to

prevent slipping.

VACUUM SHOE

1.

Remove upper link arms.

2.

Remove ball joint linkage.

3.

Disconnect

lift

cable from

shoe.

4.

Remove tension springs.

5.

Repair or replace as required.

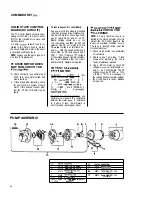

VAC SHOE ADJUSTMENT

NOTE:

When replacing

shoe or bail

adjust

shoe as follows:

With machine on smooth level

the front and rear shoe of

casting

should be parallel with surface.

1.

If

of shoe is off floor (Fig.

3),

lengthen lower adjusting rods.

2.

If

of shoe is off floor (Fig. 2),

shorten lower adjusting rods.

3.

Retighten lock nuts on adjusting

rods after completing

shoe

adjustment.

Shoe

Adjustment

-

machine on smooth

shoe, Lever should have

level surface, lower

approximately

1"

of

additional forward travel

when properly adjusted.

Lengthen or shorten lift

rods A

as required

(Fig.

4).

TO

ADJUST VAC SHOE

1.

machine moving forward check

shoe for "tracking."

2.

If shoe pulls

to the

tighten right

hand spring adjusting knob.

3.

It

shoe pulls to the

RIGHT tighten

left hand spring adjusting knob.

27.

AND CLUTCH

1.

Disconnect motor leads.

2.

Disconnect leads from clutch

3.

Remove chain. NOTE: Chain has

master link for easy removal.

4.

Remove

(4)

bolts

holding motor

to

chassis and lift out motor.

5.

brush

cap

and inspect motor

brushes periodically. Brushes should

be replaced when they reach

length or after approximately 750

hours. The gear box is

sealed and permanently lubricated

for the

of motor.

CLUTCH REMOVAL

AND

Depending on the duty cycle of the

clutch, periodic inspections and clean-

ing of the clutch parts should

be

made.

1.

Remove

bolt from center of gear unit

shaft.

2.

Remove bolt holding

ing arm.

3.

Remove sprocket from shaft. Use

bearing puller as needed.

Содержание COMMODORE CMD

Страница 11: ...COMMODORE 115V CONTROL PANEL ASSEMBLY I COMMOOOAE CONTROL PANEL ...

Страница 12: ...2 CHASSISWIDRIVE ASSEMBLY ...

Страница 14: ...COMMODORE 1 15V 14 ...

Страница 16: ...COMMODORE 115V SQtUTION RECOVERY TANKS 16 ...

Страница 18: ...COMMODORE 115V CONTROL PANE1 WIRING DIAGRAM 230VOLT CHASSIS WIRING DIAORAM 230 VOLT A I8 i 18 ...