16

OPM-114

REV B

MAINTENANCE

The ultimate aim of a preventive maintenance program is to maintain

the equipment in optimum condition, for the maximum amount of time

during it’s useful life. The detection of faults before they develop into

major problems will decrease downtime. A regular schedule of cleaning

and inspection will help assure trouble-free operation. Personnel

responsible for maintenance should set up a schedule for inspection,

and cleaning at intervals calculated to keep the equipment in good

condition. In making up a schedule, keep the following in mind:

A. New equipment must be carefully monitored until extended operation

has demonstrated that it is performing satisfactorily.

B. Old equipment requires more frequent inspection (and possibly

servicing) than similar equipment that has lower hours.

C. Time spent in cleaning, inspecting and correcting minor defects

before they become major troubles saves time in overhaul and repair.

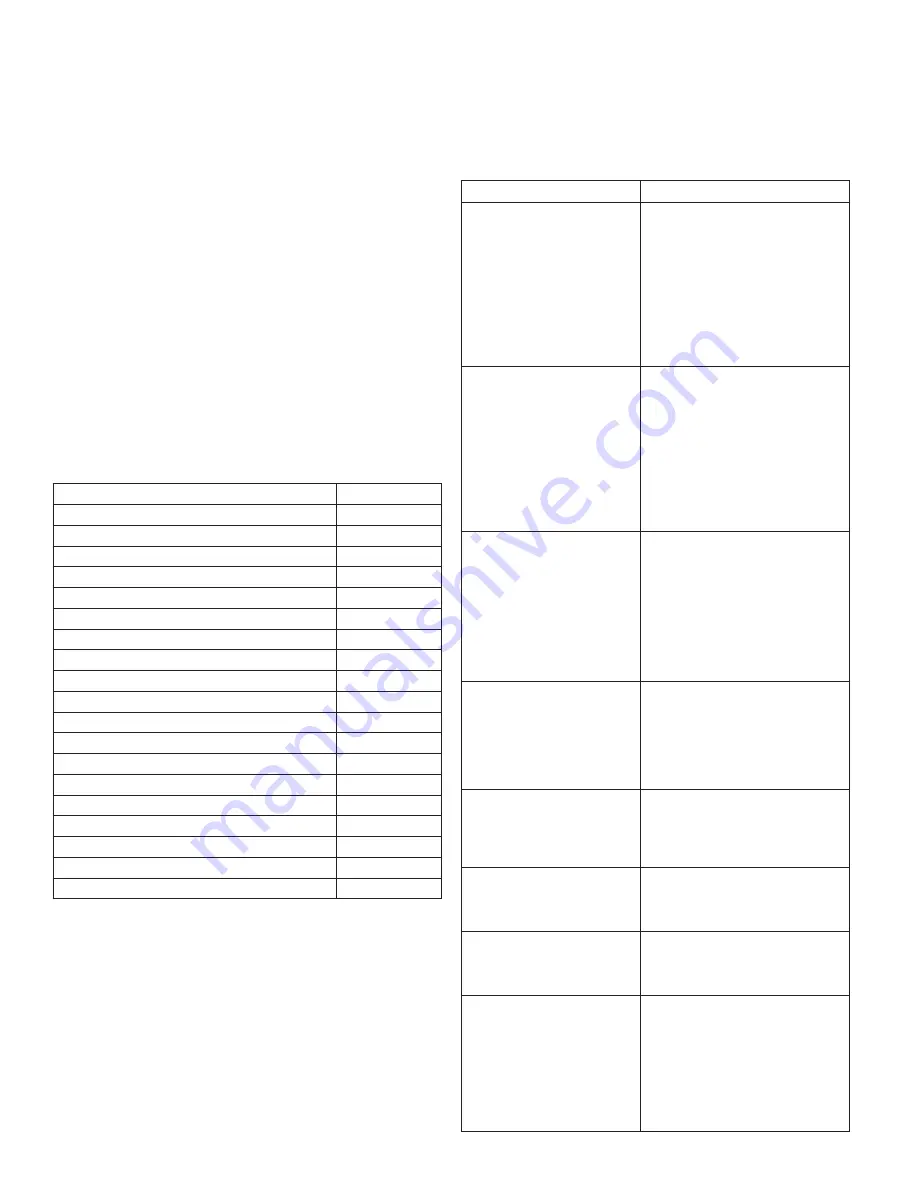

MAINTENANCE SCHEDULE

SERVICE

INTERVALS

Check Engine Oil Level

Daily

Check Coolant Level and for Leakage

Daily

Check Air Filter

Daily

Check Electrolyte Level in Battery and Clean Terminals

6 Months

Drain Water from Fuel Pre-Filter

150 Hours

Check Belts and Belt Tension

300 Hours

Check Oil Vapor Filter

300 Hours

Change Oil

600 Hours

Change Oil Filters

600 Hours

Change Fuel Filters

600 Hours

Change Fuel Prefilter

600 Hours

Check Exhaust System for Damage

6 Months

Clean Fuel Tank

6 Months

Change Auxiliary Member Belt

1200 Hours

Change Air Filter (depending on conditions)

1200 Hours

Change Coolant

1200 Hours

Change Oil Vapor Filter

2 Years

Clean Turbocharger

1200 Hours

Adjust Play in Valve-Rocker Arms and Pump-Rocker Arms

1200 Hours

* There are additional maintenance items and explanations in the

engine operator’s manual. Read thoroughly before operating this unit.

TROUBLESHOOTING TABLE

NOTE: Before doing any trouble shooting, check the digital display on

the DSE 7310 MKII. Normally, it will tell why the unit has failed. This

will shorten your trouble shooting time and in many cases, prevent the

replacement of parts that may not be defective.

Problem

Possible Causes

Unit will not crank when power fails

Digital genset not in AUTO

Transfer control switch not in

AUTOMATIC position

Incorrect wiring between ATS and genset

Defective control relay in ATS

Fuse(s) blown in the DSE 7310 MKII

Defective DSE 7310 MKII

Loose or dirty battery terminals

Defective starter

Defective start solenoid

Low/dead battery

Engine won’t crank

Low/dead battery

Blown DC fuses

Defective DSE 7310 MKII

Defective key switch

Loose or dirty battery terminals

Defective starter

Defective start solenoid

Locked up engine genset

Defective engine harness

Improper battery voltage to start solenoid,

fuel pump, or fuel solenoid

Engine cranks but will not start

Improper fuel delivery to the unit

Fuel supply shut off

Fuel tank empty

Air in the fuel system

Engine fuel solenoid has not opened

Defective fuel pump

Defective fuel solenoid

Defective engine harness

Improper battery voltage to fuel pump or

fuel solenoid

Engine starts, then stops and alarm

light comes on

Engine oil pressure is low

Engine has high water temperature

Engine has overspeed

Engine has gone into overcrank

No output from AC generator

Loss of speed signal

Loss of run signal

Engine will not come up to speed

after it starts

Insufficient fuel volume getting to the unit

1. Too small of fuel line

2. Fuel racks not open properly

Governor is defective

AC short in generator components

ATS will not transfer to Emergency

Supply (generator)

No AC generator output

Defective ATS control board. See ATS

manual

Circuit breaker open or defective

ATS will not re-transfer to normal

power

Proper power line not available at line

terminals in ATS panel

Defective ATS control board. See ATS

manual

No AC output from generator

Defective diode

Defective voltage regulator

Defective rotor

Defective stator

Defective exciter rotor

Defective exciter stator

AC short in the output leads

Defective/open generator output breaker

Wiring error