TECH SHEET - DO NOT DISCARD

PAGE 11

FOR SERVICE TECHNICIAN’S USE ONLY

PART NO. W10054150

4.

Press the Pause/Cancel button at any

time to cancel changes and exit from this

mode.

REMOVING THE FRONT

PANEL/DRUM ASSEMBLY

1.

Unplug dryer or disconnect power.

2.

Remove the lint screen.

3.

Remove the two screws holding the lint

screen duct to the top.

4.

Open the door.

5.

Push on the retaining clips located under

top of dryer on the right and left side

using a flat object such as a putty knife.

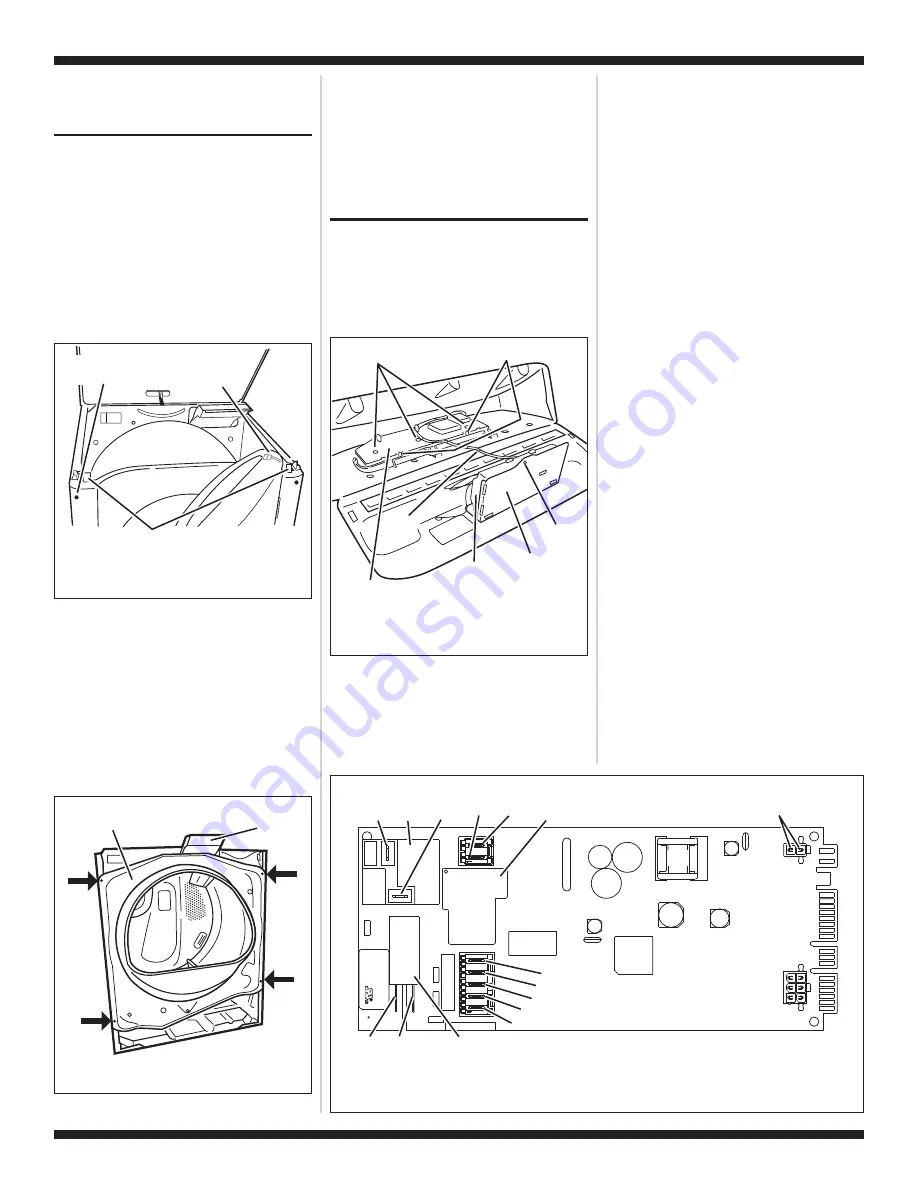

See figure 12.

6.

Slowly rotate top backwards and lean

against wall, or support with a prop rod.

7.

Disconnect the door switch wire harness

located on the right side. See figure 12.

8.

Remove the front panel/door assembly

by removing the two front cover screws at

the top of the panel inside the cabinet,

and lifting upward.

9.

Remove the front bulkhead by loosening

the upper two screws and removing the

lower two screws. See figure 13.

10.

Lower components can be accessed at

this time, however, if the drum is to be

removed, the belt must be removed. See

TEST #3, step 5, page 7.

Reinstalling the Front Panel/Drum

Assembly

Refer to preceding removal sections and

replace in reverse order

.

ACCESSING & REMOVING

THE ELECTRONIC

ASSEMBLIES

There are two electronic assemblies; the

machine control electronics and the user

interface electronics. See figures 14 and 15.

1.

Unplug dryer or disconnect power.

2.

Remove two screws from the rear of the

console assembly. Pull console towards

front of dryer to hinge open and/or

remove console.

Removing the Machine Control

Electronics

3.

Remove the wire connections to the

machine control assembly.

4.

Remove the one screw holding the

machine control assembly to the

metal bracket. See figure 14.

5.

Push in on the tab located on the back

of the machine control to slide it off

the bracket.

Removing the User Interface

Assembly

3.

Remove the wire connections from the

user interface assembly, including the

P5 ribbon cable. See figure 14.

4.

Remove the cycle selector knob from

the front of the console by firmly

pulling on it or carefully prying straight

upward.

5.

The user interface assembly is held to

the console insert panel by three

screws and two locking tabs. After the

screws are removed, lift each of the

locking tabs to remove the back cover

of the user interface assembly. See

figure 14.

6.

Remove the cycle selector switch from

the user interface assembly opening

by lifting the locking tab on the cycle

selector switch and turning the

selector switch in a counterclockwise

direction. See figure 16, page 12.

Door Switch

Wire Harness

Connector

Front Cover Screw

(Inside Cabinet)

Top Clips

Figure 12.

Slowly rotate top backwards

and support.

P9

1

5

1

P8

P14

P2

3

1

1

6

P4

1

1

8

3

P5

P3

1

P13

1

P/N XXXXXX Re

v X

Date Code

YDDD-xx

XXXX-XXX

MADE IN COO

N.O.

Black

COM

Red

Heater

Relay 1

Motor

Relay

Tan

Black-White

White

Green-Yellow

Brown

Blue

Black

Heater Relay 2

(Dual Element Model Only)

Yellow-Red

COM

Violet

N.O.

Black

Figure 15.

Machine control electronics.

Drum Face

Plate

Lint Screen

Duct

Figure 13.

Remove the front bulkhead.

Back Cover Locking Tabs

Metal Bracket

Machine Control

Electronics

Assembly

Screw

3 Screws

User Interface

Assembly Back Cover

P5

Ribbon

Cable

Figure 14.

Locate the electronic

assemblies.